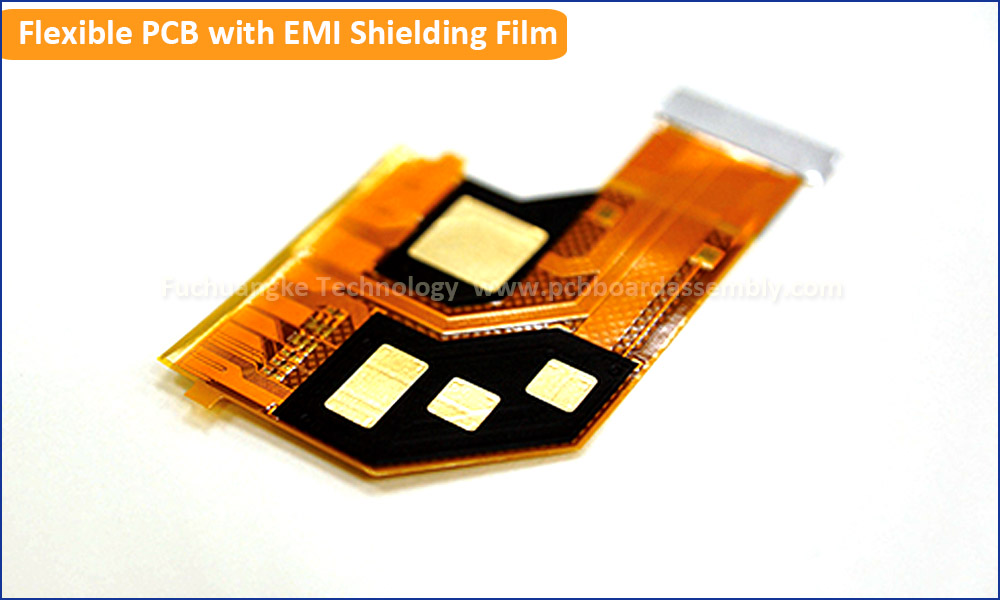

Flexible PCB with EMI Shielding Film

What’s EMI?

Electromagnetic interference (EMI), also called radio-frequency interference (RFI), when in the radio frequency spectrum, is a disturbance generated by an external source that affects an electrical circuit by electromagnetic induction, electrostatic coupling, or conduction. The disturbance may degrade the performance of the circuit or even stop it from functioning. EMI or RFI is caused by electrical pulsing. There are many devices can generate EMI including motors, power supplies and digital electronics. Except for metal shielding cover in SMT process, EMI shielding film is becoming more and more popular in the designs of flexible printed circuit (FPC) and rigid-flex printed circuit board (PCB).

EMI Shielding

Shielding can be different materials based on upon the application but must be conductive and grounded. When your flexible PCB or rigid-flex PCB application requires limits in electromagnetic and /or electrostatic interference, EMI shielding should be applied. Protective EMI shielding can be patterned, solid copper, or conductive EMI film. The shielding will be different upon the amount of EMI interface in the product, the conductivity requirements and the amount of flexing that the circuit will endure. With ever-increasing wireless communication networks in the form of mobile phones, earphones and wireless printers, EMI is becoming from many different sources even outside of the device and should be considered with critical flexible PCB and rigid flex circuit designs.

EMI Shielding Film

If you are in PCB manufacturing industry, you can always see there is a black film adhesive to the flexible PCB circuit or rigid-flex PCB. What’s this film? It’s a shielding film. Shielding film consists of an additional layer of selectively specialized laminate on the surface of the coverlays. In the material roll, the shielding films have a 3-layer construction consisting of an electrically conductive adhesive, a metallic deposition layer and an isolating layer. The isolating layer is black in color as well as friction resistant. The EMI shielding film is laminated under heat and pressure. The conductive adhesive flows into the coverlay opening which then adheres and electrically connects to the ground.

For controlling the EMI, in some FPC applications, the designer adds EMI shielding film. Many electronic PCB assemblies that utilize flexible PCB or Rigid-flex circuit are sensitive to either absorbing or emitting EMI. If EMI is left uncontrolled it can negatively impact the performance of the design and in extreme cases completely prevent it from functioning.

With EMI shielding film design, the Flexible PCB has best flexibility as well as the thinnest overall thickness. Compared to silver ink printing and copper layer design, the flex circuit cost will be lower, and the shielding capability will be in a higher degree. No need extra shielding material, like metal cover. EMI shielding film such as Tatsuta can replace the copper layer design, then to save cost without compromising on the flexibility of the board.

PCB Applications with EMI Shielding Film

| Medical Devices | Consumer Electronics |

| MRI (Magnetic Resonance Imaging) Infusion pumps Patient monitoring systems | Mobile Phone PC &Tablet Earphone |

Fuchuangke Technology specializes in Flexible PCB and Rigid-flex printed circuit board manufacturing and assembly, including prototypes and high-volume production, free DFM, and service to OEM and design companies around the world. We have rich EMI shielding film processing technology, which ensure your PCB boards can be fabricated in high quality.

View more to check our Flexible & Rigid-Flex PCB Capabilities

Quick Quote

Click the Quick Quote buttons below, you can turn to the different PCB quote pages. Just fill in the PCB specifications, upload Gerber files, BOM, Assembly Drawing and Pick-and-Place file, you will get quick quote of PCB board and PCB Assembly.

FR-4 PCB Quote Flexible PCB Quote Rigid-Flex PCB Quote IMS PCB Quote