Heavy copper technology is one of the solutions to reach the needs of modern power electronics, and heavy copper printed circuit boards are the latest trend in PCB industry. Heavy copper PCBs are highly used for high power and current applications in power supplies, welding equipment, electrical power distribution, power converters, solar panel devices, medical, automotive, aviation and etc. because the heavy copper layers are helpful for controlling the thermal dissipation and running high power and current. Our heavy copper PCB manufacturing service covers single-sided, double-sided and multilayer PCBs. Moreover, heavy copper PCB fabrication can be on FR4, Polyimide, aluminum based, copper based, ceramic based and PTFE laminate materials.

Heavy Copper PCB, also called as Thick Copper PCB, or High Copper PCB. The thickness of copper on a PCB is often discussed in terms of “weight” in ounces. A 5 oz (ounce) copper layer would mean that it is 175?m (i.e. 7mils) thick. The measurement refers to 1 ounce (28.35g) of copper being spread to cover 1 square foot (929cm2) of PCB area evenly. What’s Heavy Copper PCB? There is no a standard definition. But when the internal or external layers of copper weight that are 2oz (ounces), 3oz or more per square foot, we treat them as heavy copper boards.

What Are the Advantages of using Heavy Copper PCB?

- Plating and etching combination making straight sidewalls and negligible undercut.

- Increasing copper thickness in PTH and via sidewalls.

- Increasing range of current conductivity.

- Potential smaller board size from layering.

- Increasing strength at connector sites.

- Transferring heat to external heatsink.

- Increasing mechanical strength at connector sites and in PTH holes./li>

- Increasing the endurance to thermal strains.

- Increasing on-board high-power-density planar transformers.

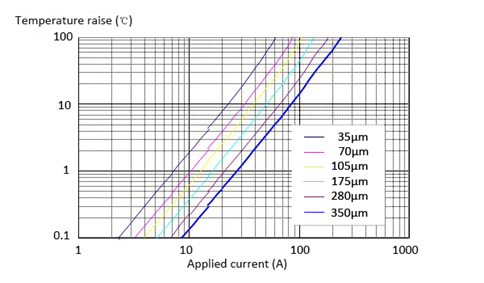

High Power Running on Heavy Copper PCBs

Heavy copper PCBs have great demand in some particular industries with the increasing demand for high power, appropriate cooling systems and some necessary considerations. With our heavy copper technology, PCBs with high power currents reaching 200 A can be manufactured.

Thermal simulation of thick Copper pattern

Heavy Copper PCB Manufacturing Capabilities:

| Heavy Copper PCBs | Thick Copper Weight | Outer layer Copper | Inner Copper | ||

| oz | mil(s) | ?m | D1/D2 | d1/d2 | |

| 2oz PCB | 2 | 2.8 | 70 | 6/7mil | 4/5.5mil |

| 3oz PCB | 3 | 4.2 | 105 | 6/10mil | 5/8mil |

| 4oz PCB | 4 | 5.6 | 140 | 7.5/13mil | 6/11mil |

| 5oz PCB | 5 | 7 | 175 | 9/16mil | 7/14mil |

| 6oz PCB | 6 | 8.4 | 210 | 10/19mil | 8/16mil |

| 7oz PCB | 7 | 9.8 | 245 | 11/22mil | 9/19mil |

| 8oz PCB | 8 | 11.2 | 280 | 12/26mil | 10/22mil |

| 9oz PCB | 9 | 12.6 | 315 | 13/30mil | 11/25mil |

| 10oz PCB | 10 | 14 | 350 | 14/35mil | 12/28mil |

For this chart, it’s obvious that we can provider 2oz, 3oz, 4oz, 5oz, 6oz, 7oz, 8oz, 9oz, 10oz heavy thick copper printed circuit board (PCB) manufacturing service to reach your high copper requirements in different high power, high voltage and high current applications.

What’s the Heavy Copper PCB Price?

Heavy copper PCB cost mainly consists of FR-4 and polyimide material, copper, etching and plating. Etching of pattern is one of the major issues to overcome for heavy copper PCB. When the copper thickness become thicker, the etching process time will be longer. With thicker copper, the heavy PCB manufacturer will put more copper and time together with more chemicals to produce such circuit boards. Depending upon the PCB specifications, especially the copper weight in each layer, heavy copper PCBs are more expensive than standard PCBs. If you don’t know which thick copper weight fits for your products, we suggest you to make heavy copper PCB protype first to verify your design. As a heavy copper PCB manufacturer China, we have enough experience and skilled production processes for such PCBs to save your cost. At Jichangsheng Technology, we support heavy copper PCB prototype and high-volume production.

Heavy Copper Printed Circuit Board Applications

- High Power Distribution

- Planar Transformers

- Heat Dissipation

- Amplification Systems

- Solar Panel Manufactures

- Power Controllers

- Welding Equipment