What is FR4 Material?

FR-4, also written as FR4. FR is the name, stands for flame retardant, and denotes that the material complies with standard UL94 V-0. The designation FR-4 was created by NEMA in 1968. UL has 4 ratings which include HB, V-2, V-1 and V-0. V-0 is the highest flame retardant. The name FR is the insulation material, applied to the epoxy glass fiber fabric used in rigid printed circuit board manufacturing. From the rigid PCB board, the insulation part you can see is epoxy glass fiber fabric.

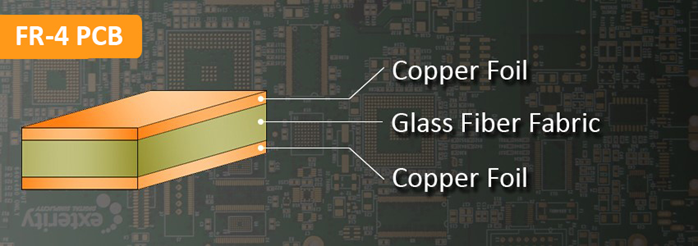

FR4 Copper Clad Lamination (CCL)

Laminating copper onto the FR4 material, we can get the most popular used rigid PCB material copper clad laminate, also written as CCL. FR4 CCL is the most widely used base material which the printed circuit board (PCB) manufacturer fabricates the bare PCBs due to its high mechanical values and electrical insulating quality. With a PCB, FR4 material only forms the primary insulating backbone. If want to make double-sided PCB or multilayer PCB, we need to use FR4 core, pre-preg (PP) and copper foil, which will be laminated with one or more layers under heat and pressure in lamination machines after traces etching.

Read on to learn more about FR-4 PCB.

What’s FR-4 PCB?

PCB is used to mechanically and electrically connect electronic components with conductive holes, tracks and signal traces etched from CLL substrate. Many years ago, PCB has been also named Printed Wiring Board (PWB) or etching wiring board if no extra electronic components was added and soldered on. Printed Circuit Board using FR4 as core material will be named as “FR4 PCB”.

FR4 Printed Circuit Board Classification

1. Upon PCB layer count

- Single-Sided (S/S), or single layer, one layer

- Double-Sided (D/S), or double layer, 2 layers, 2L

- Four Layers (4L), Six Layers (6L), Eight Layers (8L), Ten Layers (10L), … Twenty Layers (20L) or more.

Except for 1L, almost all FR4 PCB boards are even-numbered layers since the symmetric structures. When it comes to four layers (4L), people always call it as Multilayer PCB.

2. Upon thru-hole and microvia hole

- Thru-Hole board with PTH, blind and buried vias (dia.>=8mil)

- HDI board with PTH, blind and buried microvias (dia.<=6mil)

3. Upon glass transition temperature (Tg)

- Normal Tg = over 130ºC

- Middle Tg = over 150ºC

- High Tg = over 170ºC

4. Other FR4 PCB types

Specialized in printed circuit board manufacturing and PCB assembly, including PCB prototypes and high-volume production, Fuchuangke Technology is a reliable turnkey PCB manufacturer and provider in Shenzhen, China. We support manufacturing with some of the highest PCB technology and quality standards found in the industry today, like HDI boards, microvia PCB and Via-in-Pad board.