Automated X-ray Inspection (AXI), has grown as a new type technology in PCB assembly inspection. As a leading turnkey PCB and assembly manufacturer, Fuchuangke Technology provides X-ray inspection service. Similar to non-contact optical inspection, X-ray inspection produces images of the PCBA object. The image is then processed by image processing software that detects the position and size /shape of expected features for process optimization or presence /absence of unexpected /unintended objects or features for anomaly detection. Instead of visible light, it uses X-rays, typically generated by an X-ray tube that pass through the object. Opposite the X-ray emitter is a detector that either converts X-ray into visible light or sensor arrays that directly pick up the X-ray and convert it into an electronic image. The image is produced due to the different absorption of X-rays when passing through the PCBA object and can therefore structures inside the object that are hidden from outside view. Automated X-ray inspection Systems are able to monitor a variety of aspects of printed circuit board assembly production.

For designs including BGA Assembly, as well as QFN or other lead-less packages types, connections to the printed circuit board are formed beneath the body of the components themselves. As such, visual inspection and AOI inspection are not sufficient to verify a robust assembly, and we must employ X-ray inspection on the SMD components in order to meet quality assurance guidelines.

X-rays penetrate the silicon of an IC package and reflect from the metal of the connections underneath, forming an image of the solder joints themselves that can be analyzed by advanced image processing software similar to AOI. Higher-density features in the capture area create a darker resulting image, allowing for quantitative analysis to determine quality of the solder joints and compare against industry standards. X-ray inspection is really important for PCB assembly manufacturing with leadless chips.

Not only does X-ray inspection detect issues in PCB assembly, but the analysis of an X-ray image can help to determine the root cause of a given defect, such as insufficient solder paste, skewed part placement, or improper reflow soldering profile. This technique contributes greatly to our Quality Management strategy for complex components.

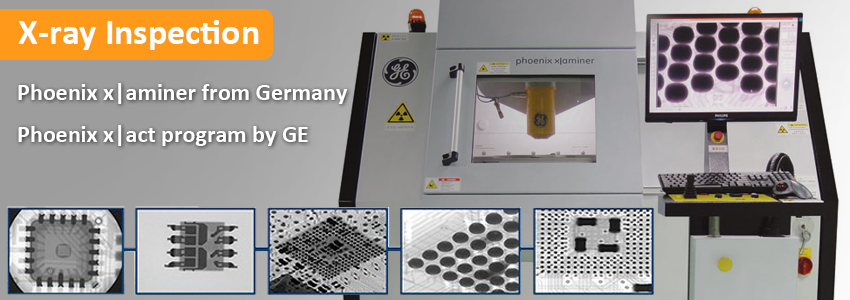

x|aminer (Phoenix) X-ray Capacity in Our SMT Assembly House

| Soldering Defects | Component Defects | BGA &CSP Defects |

| Open circuits | Lifted Lead | BGA shots |

| Solder bridges | Missing component | BGA open circuit connections |

| Solder shorts | Misaligned component | |

| Insufficient solder | Misplaced component | |

| Solder void | ||

| Excess solder | ||

| Solder quality |

With X-ray inspection service for lead-less package assembly, as a customer, you need only include the lead-less parts on BOM when they submit a PCB assembly project for quoting. To be sure that a particular part will be subjected to this testing, a note can be added to the relevant BOM row, or you can mention this requirement in the email to us.

For any further questions regarding X-ray inspection, feel free to Contact Us.

PCB Assembly Quick Quote

FR-4 PCB Quote Flexible PCB Quote Rigid-Flex PCB Quote IMS PCB Quote