Aluminum PCB, also referred as metal core PCB, IMS (insulated metal substrate) PCB and MCPCB. Metal core PCBs are well-known on their perfect thermal dissipation property. Aluminum PCB is the most common used type in all MCPCBs.

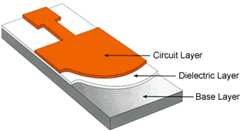

Aluminum PCB consists of copper clad laminate and thin dielectric thermally conductive and electrically insulated layer that is laminated between copper foil and Aluminum metal base. The copper foil will be etched to be desired circuit pattern while aluminum base allows the heat dissipation with the help of dielectric placed between the layers. The aluminum substrate construction is mainly divided into three layers, including copper circuit layer, dielectric layer and aluminum base layer. Read on to understand more about the Aluminum PCB layers. Moreover, aluminum is a lightweight but extremely durable material for PCB fabrication.

Circuit Layer:

Printed circuit foil with copper weight of 1oz to 3oz.

Dielectric Layer:

The dielectric layer contains a ceramic polymer that has excellent viscoelastic properties, great thermal resistance, and defends the PCB against thermal and mechanical stresses.

Aluminum Base Layer:

Base layer consists of an aluminum alloy substrate and the most commonly used thickness is 1.0mm although many alternative thicknesses are for choice.

Manufacturing Aluminum PCBs (Up to 2 layers, and multilayer hybrid PCB with FR4)

We work to be the best Aluminum PCB manufacturer when it comes to exceeding all customer expectations. We provide a wide range of electrical and thermally conductive interface pads, thermally conductive gap fillers, thermal phase change materials and thermally conductive electrically insulating materials, as well as specialized equipment for high volume manufacturing. Choosing the best Aluminum PCB supplier is key important, that LED PCB with Taiyo solder mask will improve the lifespan for the applications, such as LED lights. LED PCB with Taiyo white solder mask will not go dark, and not to affect the color temperature of the LED SMDs. Aluminum based PCBs or Copper based PCBs can consistently increase durability and long-term reliability of a final product through temperature control and associated reductions in failure rates. Metal core designs also deliver better mechanical stability and lower thermal expansion levels than other available materials.

View more to check our Metal Core PCB (MCPCB) Capablities

Nowadays, aluminum PCB applications are very wide which contributes to its high heat dissipation property. And Aluminum LED PCB is the most commonly used one. We always see the LED PCB light everywhere indoor and outdoor, like indoor and outdoor light, stage light, street light, automotive front light, stadiums and arenas light, industrial and horticulture light, and etc. Besides, Aluminum circuit boards are widely applied for telecommunications, power supply and modules, audio devices, computer and etc.

Aluminum printed circuit boards have a unique set of advantages compared to other base materials:

Inexpensive – Aluminum is easy to mine and refine, which makes it significantly less expensive than that of other metals. Besides, the Aluminum PCB manufacturing costs associated with products using aluminum are also less expensive.

Better Heat Transfer – High temperatures are always the cause of heavy damage to electronic devices and products. Aluminum conducts and dissipates heat away from critical parts to minimize damage to the PCB assemblies.

Good Durability – Aluminum is stronger and more durable than FR4 CCL and flexible PCB material.

We work to be the best Aluminum PCB manufacturer when it comes to exceeding all customer expectations. Aluminum PCB boards can consistently increase durability and long-term reliability of a final product through temperature control and associated reduction in failure rates. We provide quick-turn Aluminum PCB manufacturing service all over the world. The Aluminum PCB prototypes can be manufactured in 24 hours to 7 days, which is different from single-sided aluminum PCB prototype or double-sided aluminum PCB prototype.

Want to find an Aluminum PCB supplier? No find more, but Jichangsheng Technology. Just Contact Us, or get quote on IMS PCB Quote page.