One of the most important parts of the surface mount (SMT) assembly process is the application of solder paste onto the printed circuit board (PCB). The aim of solder paste printing is to accurate deposit the correct amount onto pads to be soldered. This is achieved by screen-printing the solder paste through a SMT Stencil. It is widely believed that this part of the process, if not controlled correctly, accounts for the majority of assembly defects. It is said that 60% to 90% of soldering defects are related to solder paste printing defects.

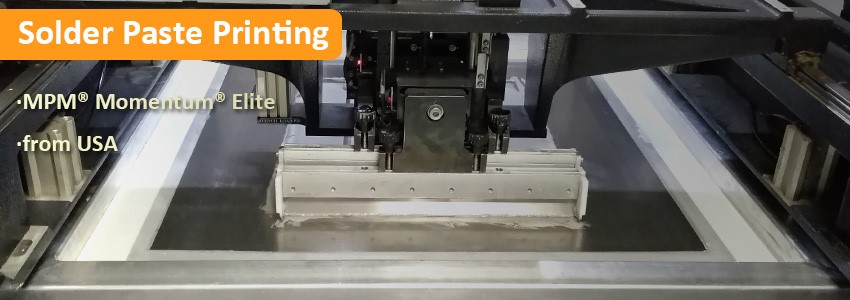

For becoming a leading turkey PCB manufacturing and assembly supplier, and for forming high quality solder paste, our PCB Assembly facility is equipped with Automated Solder Paste Printer (MPM® Momentum® Elite) from USA to fulfill the assembly manufacturing capabilities. The Elite is the top-performer of the Momentum series, boasting the highest throughput and shortest cycle times of all. Tighter performance tolerances mean higher repeatability with fewer defects. The Auto solder paste printer has the following features:

-Applicable for all kinds of fine pitch ICs.

-Solder paste height monitor

– Alignment repeatability: ±12.5µm @ 6sigma, Cpk >2.

-Printing precision: +/-20µm

-Minimum Board Size: 50.8mm x 50.8mm (2’’x2’’)

-Maximum Board Size: 609.6mm x 508mm (24’’x20’’)

* A dedicated work holder is required for boards with an X size greater than 20”.

-Board Thickness: 0.2mm (0.008”) to 5.0mm (0.20”), up to 6.0 mm (0.24”) without top clamp foils.

Solder paste printed deposits are essential to forming defect-free solder joints, the electrical and physical connections between electronic components and the PCB assembly. The key parameters of an effective solder paste printing process of automated printing are as following:

-Squeegee speed

-Squeegee pressure

-SMT Stencil separation speed

-SMT Stencil cleaning

-SMT Stencil and squeegee condition

-PCB support strength

-Print stroke

-Type, storage and handling

-Inspection

The printing stage of the assembly process is vitally important. If there are errors introduced at this stage there will be “knock on” effects throughout the process. But don’t worry, in our longstanding processing, our experienced technicians can handle the printing process perfectly, which can ensure the solder paste printing with high quality.

At our PCB assembly house, we support rigid PCB, flex circuit and rigid-flex PCB assembly. Click the buttons below to get quick quote on your bare PCB and/or PCB assembly project.

FR-4 PCB Quote Flexible PCB Quote Rigid-Flex PCB Quote IMS PCB Quote