Printed Circuit Board Prototype

Printed circuit board prototype is the most critical period of time in electronic hardware development stage to verify your design is right before start PCB mass production. Circuit board prototypes used to the nightmares of a lot of electronic hardware designers. As a one-stop PCB and assembly manufacturer, we can turn your designs around fast from PCB prototyping to PCB assembly, and terminate the nightmares. We offer quick PCB prototype service with high quality and affordable prices.

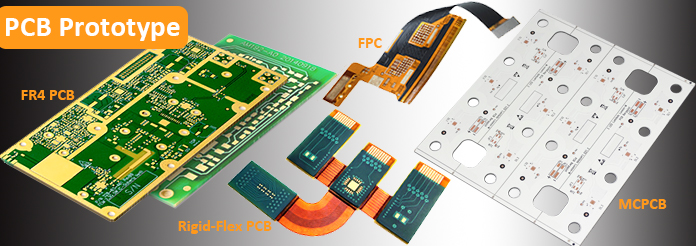

Which types of PCB prototype board we support?

We are a China PCB manufacturer located in the greatest electronic market city Shenzhen, our PCB manufacturing includes Rigid PCB, Flexible PCB and Rigid-flex PCB. The PCB layers differ from 1 layer, 2 layers, 3 layers, 4 layers, 6 layers, 8 layers, 10 layers to 20 layers upon different PCB types. The PCB prototype boards we support like below,

- Standard PCB

- Flexible PCB

- Rigid-flex PCB

- Aluminum PCB

- HDI PCB

- Multilayer PCB

- Heavy Copper PCB

- High-Tg PCB

- Halogen Free PCB

- Impedance Controlled PCB

- Hard Gold PCB

- Half-holes PCB

PCB Prototype Fabrication Meets High-Quality Standards

The PCB market always has huge and quick demand of PCB prototyping service. We offer fast PCB prototype services for quick turn prototype PCB at high quality and low cost. Our factory passed ISO9001:2015 quality management system certificate and ISO14001:2015 environmental management system certificate. All our workmanships are strictly deducted according to IPC standards, and our professional in-house quality control team will verify all of the workmanships meets customer’s requirements and each regulation. Upon your custom PCB requirements, we support PCB prototype manufacturing with 3-7 days, compared to 6-18 days of standard PCB service and 15-25 days of HDI PCB service.

What Are the Advantages of Printed Circuit Board Prototyping?

All electronic products should take printed circuit board prototyping for function testing no matter in low volume or in mass production. Here are some benefits of making PCB board prototype:

- Design Fault Inspection is one of the major reasons why circuit board prototyping is done. The technical or human faults can be easily detected and improved as per product requirement before finalizing the design.

- Product Characteristics Inspection is another reason using PCB prototyping. Sometimes, the practical values of the product may differ slightly from the theoretical values considered during the design of the product. These values need to be checked and updated upon the prototype PCB.

- Proto PCB will be helpful for checking Product Endurance. When a product enters the market, it has to withstand innumerous conditions from temperature variations, power variations, shock resistivity, etc.

- If the product is intended for large number of consumers, it will be put into mass production. Once the final design of printed circuit board is submitted for mass production, you can’t undo prototyping. Redoing it will cost a huge loss.

- Production Process: Other process like design of the product, packaging, etc. depends on the design and size of the PCB which can be confirmed only with the prototype PCB board. So, this is another most important factor.

Considering of so many benefits of PCB prototypes, no find more, but us to be your supplier to produce the PCB proto. We are aChina PCB Prototype manufacturer with our own PCB manufacturing house in Shenzhen.

FR-4 PCB Quote Flexible PCB Quote Rigid-Flex PCB Quote IMS PCB Quote