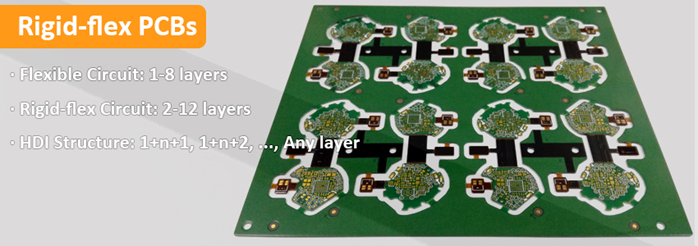

Rigid-flex PCB, also called Flex-Rigid PCB, or Rigid-Flex Board, which has been used for more than 2 decades. Flex-rigid PCBs derive their name from the fact that they use a combination of flexible and rigid circuitry and rigid circuitry areas. Like FR-4 PCBs, rigid-flex boards have multilayers but generally have more than conventional designs. Nowadays, they are also widely used in commercial, industrial and consumer electronics, like wearable smart watch, printer, UAV drones, earphone and etc.

In most rigid-flex printed circuit boards, the circuitry consists of multiple flexible circuit inner layers selectively attached together using an epoxy pre-preg bonding film, similar to a multilayer flexible circuit. However, a multilayer rigid flex circuit incorporates a board externally, internally or both as needed to achieve the design.

Flex-rigid printed circuit boards combine the best of both rigid boards and flexible circuits integrated together into one circuit. The 2-in-1 circuit is interconnected through plated-through holes. Flex rigid circuits provide higher components density and good quality control. Designs are rigid whether extra support is required and flexible around corners and areas requiring extra space.

Click to check our advanced standard and HDI Flexible and Rigid-Flex Circuit Board Capabilities, please click Here to check.

Rigid Flex PCB Materials?

Insulators-Flexible substrate and coverlay materials are available in a variety of thicknesses. Here are some common insulators:

- FR-4

- Polyimide (PI)

- Polyester (PE)

- Solder Mask

- Flexible Solder Mask (part area soldermask)

- Photo imageable coverlay

- Stiffener (PI, FR4 and stainless steel)

- EMI Shielding

Conductors– the circuit copper traces

- Rolled annealed (RA) copper

- Electro deposited (ED) copper

Adhesive-Adhesive selection depends on customer needs and conductor thickness. Here are some common adhesives:

- Epoxy

- Acrylic

- Prepreg (PP)

- Pressure sensitive adhesive (PSA)

- Adhesive-less substrate material (in multilayer flex rigid PCB need manufacture with another individual adhesive)

Surface Finishes – The surface finish depends on each customer’s SMT assembly requirements and the application of the finished product. Here are some common surface finishes RoHS complaint for flex-rigid PCBs:

- Immersion gold

- Immersion Gold

- Immersion Silver

- OSP

- ENEPIG

- Hard Gold

Jichangsheng Technology is a industry leader in manufacturing rigid-flex boards and flexible circuits with more than 10 years experience, specializes in custom single-sided to multilayered standard, hybrid and HDI flexible and rigid-flex PCB fabrication. Filling in your rigid-flex PCB specifications and upload gerber files to our website, you can get a quick quote.