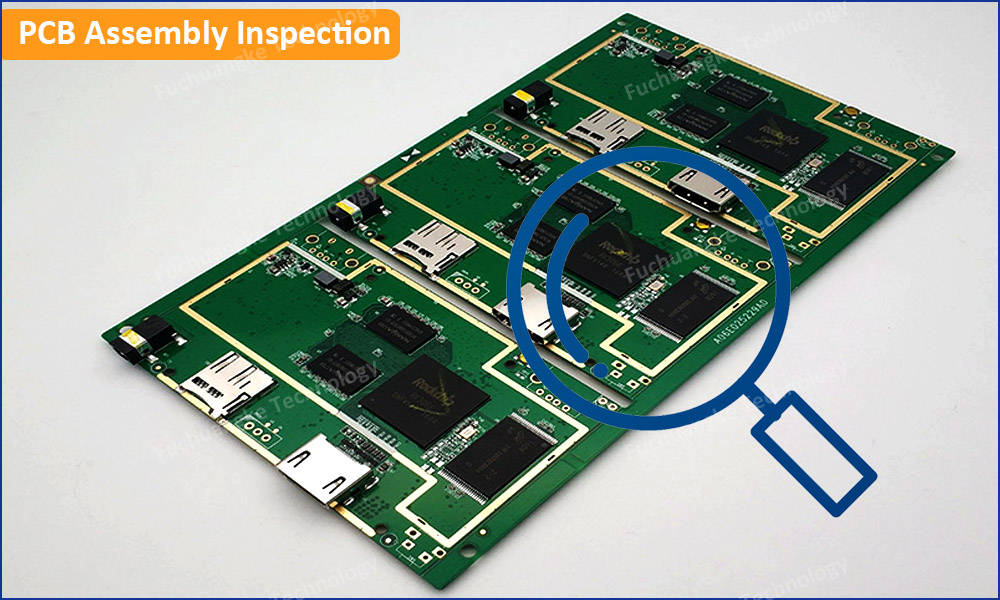

Overview of Popular PCB Assembly (PCBA) Inspection

High-quality PCB assemblies (PCBAs) have become a major requirement in electronics industry. The PCBAs serve as the integrated component of various electronics. The functioning of various electronic devices will be at stake, if the PCB assembly manufacturers fail to perform due to production errors. For avoid the risks, nowadays, the PCB and assembly manufacturers are performing various type of inspections on PCBAs during different manufacturing steps. This blog discusses various PCBA inspection techniques and the types of defects analyzed by them.

PCBA Inspection Methods

Today, due to the increasing complexity of printed circuit boards, identification of manufacturing defects is challenging. Many times, PCBs may have defects such as opens and shorts, wrong orientation, soldering inconsistency, misalignment of components, wrong component placement, defective non-electrical components, missing electrical components, and so on. To avoid all these, Turnkey PCB Assembly Manufacturer employs the following inspection methods.

All the above-discussed techniques ensure accurate inspection of electronic PCB assemblies and help PCB assemblies ensure their quality before leaving the facility. If you are considering PCB assemblies for your next project, it’s important that source from trusted PCB assembly services such as Fuchuangke Technology, which has been delivering PCB assembly to its clients in industry sectors since our inception.

First Article Inspection

The quality of production always depends on the proper functioning of SMT. Hence, before the start of high-volume assembly and production, PCB manufacturers employ first article inspection to ensure the SMT equipment is properly set. This inspection helps them detect vacuum nozzles as well as alignment issues, which can be avoided during volume production.

Visual Inspection

Visual inspection, or Naked-Eye inspection is one of the most common inspection techniques employed during PCB assembly. As the name indicates, this involves inspecting the various components through eye or detectors. The choice of equipment will depend on the positions to be inspected. For instance, component placement and solder paste printing is visible to naked eyes. However, solder paste deposition and copper pad can be viewed only using a Z high-detector. The most common type of visual inspection is carried out at reflow joints using a prism, where the ray of light reflected is analyzed with different perspectives.

Automated Optical Inspection

AOI is the most common, yet comprehensive visual inspection method employed for identifying defects. AOI is usually performed using multiple cameras, light sources, and programmed LED libraries. The AOI system clicks images of solder joints at different angles, and skewed components, too. Many AOI systems can inspect 30-50 joints in a second, which helps minimize the time taken to identify and correct defects. Nowadays, these systems are employed during various phases of the PCB assembly. Earlier, AOI systems were not considered ideal for measuring the height of solder joints on the PCBs. However, with the advent of 3D AOI systems, this has become possible. In addition to this, AOI systems are ideal for inspecting complex shaped components with pitches measuring 0.5mm.

X-ray Inspection

The demand for denser and compact-size circuit board assembly is increasing, owing to their utilization in miniature devices. Surface Mounted Technology (SMT) has emerged as a popular option among PCB manufacturers who want to design dense and complex PCBs with BGA package components. Although SMT has helped reduce the PCB package size, it has also induced several complexities which are not visible naked eyes. For instance, there may be 15,000 solder connections in a small chip packages (CSP) created using SMT, and it is not easy to verify them with naked eyes. This is where X-ray is employed. It’s capable of penetrating the solder joints, and identifies missing balls, solder disposition, misalignment, and many more. The X-ray penetrating through chip packages that have connections underneath, densely packed boards as well as solder joints.

All the above-discussed techniques ensure accurate inspection of electronic assemblies and help PCB assemblers ensure their quality before leaving the facility. If you are considering PCB assemblies for your next project, it’s important that you source from trusted PCB assembly manufacturer like Fuchuangke Technology.

Quick Quote

Click the Quick Quote buttons below, you can turn to the different PCB quote pages. Just fill in the PCB specifications, upload Gerber files, BOM, Assembly Drawing and Pick-and-Place file, you will get quick quote of PCB board and PCB Assembly.

FR-4 PCB Quote Flexible PCB Quote Rigid-Flex PCB Quote IMS PCB Quote