How to Reduce Costs of Your Turnkey PCB Assembly Projects

At Fuchuangke Technology, we totally understand it is extremely important to reduce the cost of PCB manufacturing and PCB assembly for your turnkey PCB assembly projects to reach your budget or cost-saving. No matter it is a low-volume or a high-volume PCB assembly project, we strive to reduce the manufacturing and assembly costs of our customer’s printed circuit boards (PCBs) without sacrificing quality or turnarounds. We access to every assembly project from professional engineering point of view, which means we review and evaluate each PCB design on a case-by-case basis to determine what features may be affecting the cost of manufacturing, and how these features might be changed without compromising the quality or functionality of the final PCBs or PCB assemblies.

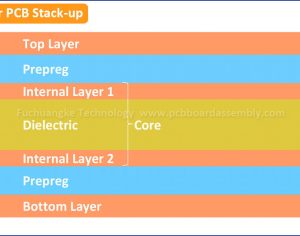

We should start from addressing PCB manufacturing costs by examining various choices, such as PCB size, layer count, PCB material, minimum trace width and spacing, copper and dielectric layer thicknesses in the stack-up, buried or blind vias type, standard thru-hole or HDI board type, Via-in-Pad or not, hole or via density and pad qty per square meter and panelization options. We can reduce PCB manufacturing costs greatly if the minimum trace width and spacing over our manufacturing capabilities to common parameters, if buried/blind vias or vias on SMT component pads are removed from the design, or if 3 lamination circles can be modified to 2 lamination circles or 1 lamination cycle in thru-hole PCB board. There are a lot of suggestions to reduce the PCB cost after reviewing your gerber files and fab notes.

PCB Size

A misconception for reducing PCB costs are based on the size of the PCB board. By reducing the PCB size, the overall cost can be reduced. In fact, it is wrong because PCB cost is not only related to square meter, but a lot of other factors, although this is normally true for common size of the printed board. But when reducing the size of a small printed circuit board, which may increase the cost. Taking a 50x50mm module board as example. The component quantities are certain, when you want to reduce the PCB cost on this concept, the designer has to reduce the size may by increasing the layer count, decreasing minimum trace width/spacing, reducing the spacing between SMD components, or adding buried/blind vias, or via-in-pad. These new features will significantly increase the PCB manufacturing complexity and its cost. Similarly, decreasing the material used by drillings can also increase the cost as well since the hole density or hole qty per square meter is increased.

Panelization

Many people ignore panelization, no matter it is single PCB design panelization, or multiple PCB design panelization, both of them are great way to optimize your project in terms of cost. When there are 2 or more turnkey PCB and assembly projects from you, we can check at panelizing those different designs together in order to reduce the overall tooling and PCB set-up cost and improve the SMT assembly efficiency. Panelization size is not the bigger, the cheaper or better. Before deciding how many pieces panelized in the Set, it’s recommended to check our manufacturing capabilities because too big or too big will increase the PCB cost. If have to panelize a lot of single pieces in set, you need to consider whether accept x-out. If don’t accept x-out, which will increase the PCB cost. At the meanwhile, the panel with x-out in different directions or places will increase the PCB assembly cost. That’s because the SMT machine program is fixed and applicable for single pieces PCB on the set to assembly. If some one of them is x-out, the SMT technician need to manual adjust to not assemble the x-out board. This extra work will increase the labor and delivery time, especially when the PCB assembly order is with large quantities.

Surface Finish

Anyone involved within PCB industry understand that PCBs have copper surface finish on their surface. If they are left unprotected then the copper will oxidize and deteriorate, making the printed circuit board unusable. It’s known that ENIG is more expensive than HASL (/HALF) or OSP, which will increase the PCB manufacturing cost. But don’t ignore ENIG has flat surface, good for PTH and fine pitch SMD assembly and long shelf life. That’s why we always encourage our clients to opt for ENIG to get high assembly stability even if it will increase a little PCB cost.

BOM Cost

For turnkey PCB projects, we will provide electronic components sourcing service to our clients at the same time of PCB manufacturing and PCB assembly services. We will perform thorough assessment of the Bill of Materials (BOM). In this assessment stage, we will find out the most expensive components, like the main chip or other ICs in your BOM to determine if we can get the part(s) from another authorized vendor for a lower price. Besides, we will discuss with the client at the very beginning whether there are any cheaper alternative components they are willing to use which could cut the cost to assembling their printed circuit boards. If unacceptable, we will source 100% originals. If accept and provide the alternative part numbers, we will quote on the alternatives. In another situation, some clients can not provide alternative part numbers. But don’t worry, our experienced professionals will find them and send for confirmation, which will save the time and energy of our clients. Except for the top ranked online components distributors, we also established our stable components supply chain, which can offer lower prices for components. If your PCB assembly project has a tight budget, it’s better for our clients to prepare target BOM pricing for each line. In this way, we can save time to check whether your target is applicable in our size. As well, if you have pre-arranged pricing with your own vendors, we can purchase the parts from your vendors, or accept them as consigned parts.

Component Packages

For your PCB assembly and Turnkey PCB project, we have several more way to help you to cut down on full turnkey assembly and consigned PCB assembly projects. A common way to decrease assembly costs is to remove extremely small passive packages. Switching 0201s to 0402s can be a relatively easy change and can reduce assembly cost as much as 5 – 10%. In addition, lead-less package types such as QFNs and BGAs require extra manufacturing care when assembling, to ensure that they are accurately alignment with footprints. By replacing these components for parts with extending leads, such as QFPs, the PCB assembly cost can be substantially reduced overall.

Quick Quote

Click the Quick Quote buttons below, you can turn to the different PCB quote pages. Just fill in the PCB specifications, upload Gerber files, BOM, Assembly Drawing and Pick-and-Place file, you will get quick quote of PCB board and PCB Assembly.

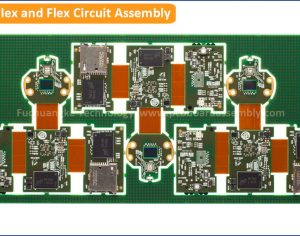

FR-4 PCB Quote Flexible PCB Quote Rigid-Flex PCB Quote IMS PCB QuoteA trusted Turnkey PCB assembly manufacturer always give suggestions to clients how to save costs but not sacrificing the quality or functionality in the PCB assembly projects from the professional point-of-view. Fuchuangke Technology is a reliable supplier with such property to help our clients in all possible considerations. Not finding more but just us.