How to Export Drill Files from PCB Design Software

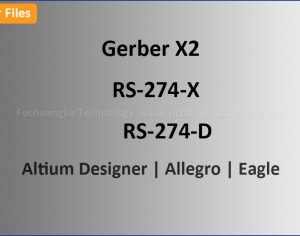

PCB files have many formats, but the Gerber files with RS-274X or RS-274D and drill files are the preferred files for printed circuit board (PCB) fabrication by PCB board manufacturers. In this PCB blog, we will talk about how to extract/export Holes or vias files from different famous PCB design software. Fuchuangke Technology is a turnkey PCB and assembly manufacturer, here tell you how to export drill frils from different PCB design software.

The holes and vias on PCB board are responsible for electrical connections between layers and corresponding functions a board will implement according to PCB design requirement. The PCB board won’t work unless they are suitably designed or fabricated. Except for suitable design, finding a professional PCB board manufacturer is very important.

The information of holes and vias’ size, layer location, coordinates is included in the drill data. And drill data (file) generally has two kinds, one is NC drill file, and the other is laser drill file. For most PCB design engineers or hardware engineers, they know how to generate or extract the drill file. Hope this article will be helpful for those who don’t know how to export drill files.

The information of holes and vias’ size, layer location, coordinates is included in the drill data. And drill data (file) generally has two kinds, one is NC drill file, and the other is laser drill file. For most PCB design engineers or hardware engineers, they know how to generate or extract the drill file. Hope this article will be helpful for those who don’t know how to export drill files.

How to export Drill File from Altium Designer?

In the user interface (UI) of Altium Designer, click in order

File->Fabrication Outputs->NC Drill Files

You will find the NC Drill Setup dialogue in which options need to be specified including NC Drill Format, Leading/Trailing Zeros, Coordinate Positions and etc. the size Unit in NC Drill files can be either inches or millimeters that should be compatible with that of Gerber Files.

(Digits) Format: Three options, 2:3, 2:4 and 2:5 are available. What’s the meaning of each digits’ format? The first number stands for integer digit, and the second number stands for decimal digit. 2:3 has the lowest resolution and 2:5 has the highest resolution. In fact, the CAM software has more options, such as 4:5. So there is no need to worry whether your PCB fabrication supplier can meet the resolution or not because of nowadays advanced NC and laser drilling machines. Of course, you can choose 2:3 if your PCB board no need highest resolution, or 2:5 is recommended.

Leading/Trailing Zeroes: In Altium Designer, it’s required to choose from the 3 available options, including Keep leading and trailing zeroes, Suppress leading zeroes and Suppress trailing zeroes. In CAM software, it is Zero Suppression. But no matter what the name is, Zero suppression drives Drill file to be fit and neat. And the intention is to reduce the file data through suppressing zeroes in drill coordinates. But which one to choose? It always relies on the PCB design engineer’s habits and convenience. If you tick Suppress leading zeros, starting zeroes in the drill file will be removed. If you tick Suppress trailing zeroes, ending zeroes will be removed.

Other: You can choose any or all if in demand for your design. If determined, just press OK to extract the Drill file(s) that will be saved in the default path of sub-folder under the folder containing Project File.

How to export Drill file from PADS?

In the user interface (UI) of PADS, click in order

File->CAM->Define CAM Documents

When it comes to drill layer, select it and click Edit whereas for layers with no demand of drilling, directly click Add. In Edit Document dialogue, press Drill and Device Setup button to specify format of NC Drill files in NC Drill Setup window. To specify format of NC Drill file, firstly press Excellon button at the left top in NC Drill Setup window. In this window, you can a few items similar to other PCB design software.

Output Type: select ASCII.

Units: You can choose from Metric and English

#of Digits: Many options in Leading and Trailing, you can choose upon precision requirement.

Zero Suppress: You can choose from None, Leading and Trailing

Coordinates: You can choose from Absolute and Incremental

For the items in Format String and Speed/Feed, you no need adjust and keep them as themselves, except you have special requirements.

If all setup finished, you can press OK button to export the drill file from PADS.

How to Export Drill File from Cadence Allegro (OrCAD)?

The default format of NC drill files exported by Cadence Allegro is not Excellon. Before export, it’s necessary to set NC Parameters by clicking Manufacture->NC->NC Parameters to open NC Parameters dialogue. In this dialogue, items of Output file and Excellon format need to be determined.

Code: ASII is preferred since it is a newer code compared to EIA.

When it comes to Excellon format,

Format: it’s leading and trailing digits, you can set upon demand

Offset: If no special requirement, you can set (X, Y)=(0,0)

Coordinates: you can tick one from the 2 options, Absolute and Incremental

Output units: English or Metric

Zero Suppression: you can tick one from the 4 options, Leading zero suppression, trailing zero suppression, Equal coordinate suppression, and Enhanced Excellon format.

When setup finished, you can click Close to end the NC Parameters dialogue. Then comes to NC Drill dialogue by clicking Manufacture->NC->NC Drill. After finish determining items in this dialogue, press Drill to end up Drill Files export process. The exported Drill files can be found in the default folder.

The drill file export process in different PCB design software has different preferences but most items are similar. Now, you can compress the gerber file and Drill files into one folder and send the .zip/.rar file to the PCB fabricators.