How to Prevent Multilayer Rigid-flex PCB Manufacturing Defects?

Multilayer Rigid-flex Printed Circuit Board (PCB) Manufacturing involves several intricate steps, which must be executed with utmost care. A minor layout, manufacturing or SMT assembly flaw can lead to overall PCB board failure, which will waste you a lot of time and money. Fuchuangke Technology is the flexible and rigid-flex circuit board manufacturer, in which the skilled and well-trained engineers and technicians are dedicated to provide the best one-stop PCB solution from PCB manufacturing to PCB assembly all over the world. The effort put in each PCB manufacturing process enables highest quality rigid-flex circuit board building.

It is always better to prevent any design and rigid-flex circuit board fabrication faults at the earliest they may cause major defects. From this PCB blog, you can minimize the number of defects during the board fabrication through considering some standard rules of multilayer rigid-flex PCB board.

Follow them listed below during a multilayer Rigid-flex PCB fabrication.

- Do DFM (Design for Manufacturing) before everything. If find us, we provide Free DFM. Check whether the main factors are manufacturable, including stack-up, trace width/spacing, via construction, via-in-pad, thickness of each dielectric layer and copper layer, and etc. If you are a designer, don’t know the Manufacturing Capabilities of your multilayer rigid-flex PCB supplier, you can ask the manufacturer to do it.

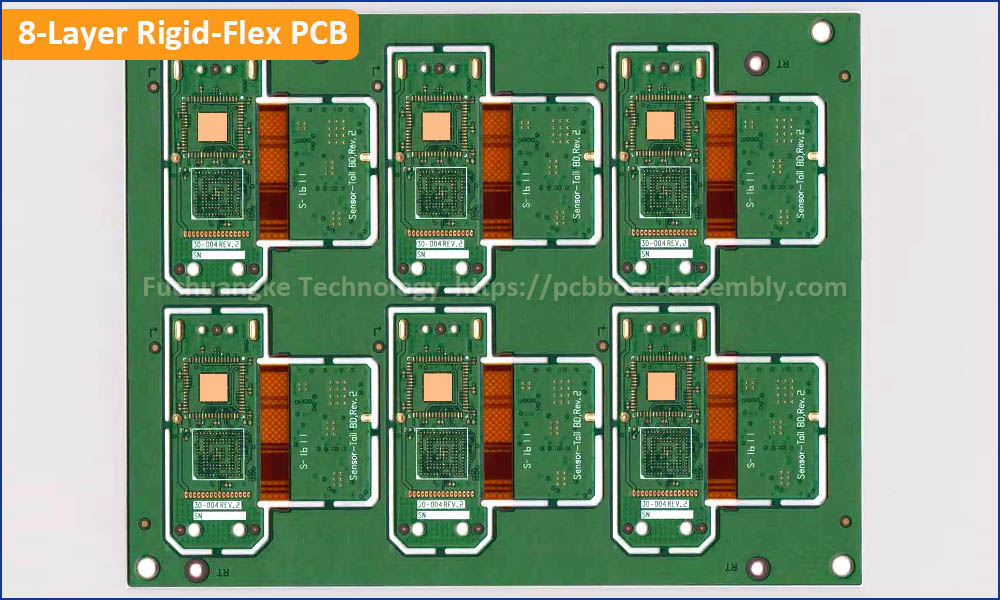

- When the DFM is done, the manufacturer should prepare the right type and amount of materials before FCCL and rigid CCL materials cutting process, which will ensure the flexibility of flex part(s) in your multilayer rigid-flex circuit board. Just imaging, if your application demands for an 8-layer rigid-flex PCB circuit board that should bend during enclosure assembly and then should remain in a fixed position. How should the PCB manufacturer do? If one of the materials is wrong, the demand cannot be met. Thus, the PCB manufacturer and supplier should prepare and use the right kind of copper, PI (Polyimide), adhesives and coverlay that allow you to do so.

- Miniaturization is still the determining trend in micro electronics that means smaller and more efficient systems which should be more cost-effective than current situations. Their best-known representative Rigid-flex PCB circuit boards being, are those built-in smart mobile phones and Tablet PCs. It is suggested to keep your circuit board small, and it’s better to use a set of smaller circuits instead of a singular large circuit if your product requiring small size or enclosure space limited. As you know, small multilayer rigid-flex circuit board manufacturing is cheaper than large sized.

- In our rigid-flex PCB manufacturing practices, we always find some new design, especially those rigid-flex PCB prototypes, the designers always prefer to bend a flex part at the corner. These guys may not know such design at the corner is likely to break the rigid-flex board in assembly or in repeat bending many times. However, if your rigid-flex PCB design demands bending at corners, you can make a gentle curving, or use conical radius bends.

- Copper used in a multilayer rigid-flex PCB circuit board has a tendency to detach from the substrate. Hence, it is essential to provide support for the copper to prevent it from detaching. Even if you are using surface mount pads and non-plated-through pads, consider using it along with some extra measures like coverlay mask to anchor pads.

- For getting quick-turn rigid-flex circuit boards, some PCB manufacturers ignore the tolerances from the customer, or even to sacrifice the quality for seizing delivery time. The key factor to a qualified multilayer rigid-flex PCB is to strictly control the tolerances. If some tolerances cannot meet the manufacturing capabilities, the rigid-flex supplier should come up with them at the initial EQ stage, and find out the best manufacturing solutions to the customer, and the any tolerance change should ensure high yield in afterwards high-volume production.

- In multilayer rigid-flex PCB production, due to the its flexibility and asymmetrical copper circuitry, the finished PCB will be easier to warp or twist compared to rigid PCB board. The root reason for this defect is the force tension between copper layers are different. We suggest to avoid laying traces over each copper layer in the same direction, and recommend to stagger the traces of the rigid PCB part(s) to achieve distribution of tension between copper layers. Of course, our experienced CAM engineers will tell you how to modify if the same direction traces layout is required. This is one of some reasons why we are a leading multilayer rigid-flex PCB manufacturer and supplier.

- If the power and/or ground plane must be placed on a flex circuit, you can consider using either solder copper pours or hatched polygons to reach the purpose of enhancing or retaining the PCB’s flexibility.

- What’s Dupont? We always see Dupont material in the fab notes. Dupont is the first company which create using PI (Polyimide) based material to manufacture flexible circuit board. Dupont is almost the same name as PI in the mind of customers from America and Europe countries. Dupont produces PI based FCCL, but there are a lot of manufacturers who also produce PI based FCCL, like Taiflex, ITEQ, Shengyi and etc. It is recommended to use other brands’ FCCL in your next designs to save cost to your Rigid-flex PCB project since Dupont materials is much more expensive than them.

Quick Quote

Click the Quick Quote buttons below, you can turn to the different PCB quote pages. Just fill in the PCB specifications, upload Gerber files, BOM, Assembly Drawing and Pick-and-Place file, you will get quick quote of PCB board and PCB Assembly.

FR-4 PCB Quote Flexible PCB Quote Rigid-Flex PCB Quote IMS PCB Quote