Routing

- In PCB design, wire routing, commonly called simply routing, is a step in the design of printed circuit boards (PCBs) and integrated circuits (ICs). It builds on a preceding step, called placement, which determines the location of each active element of an IC or component on a PCB. After placement, the routing step adds wires needed to properly connect the placed components while obeying all design rules for the IC. Together, the placement and routing steps of IC design are known as place and route.

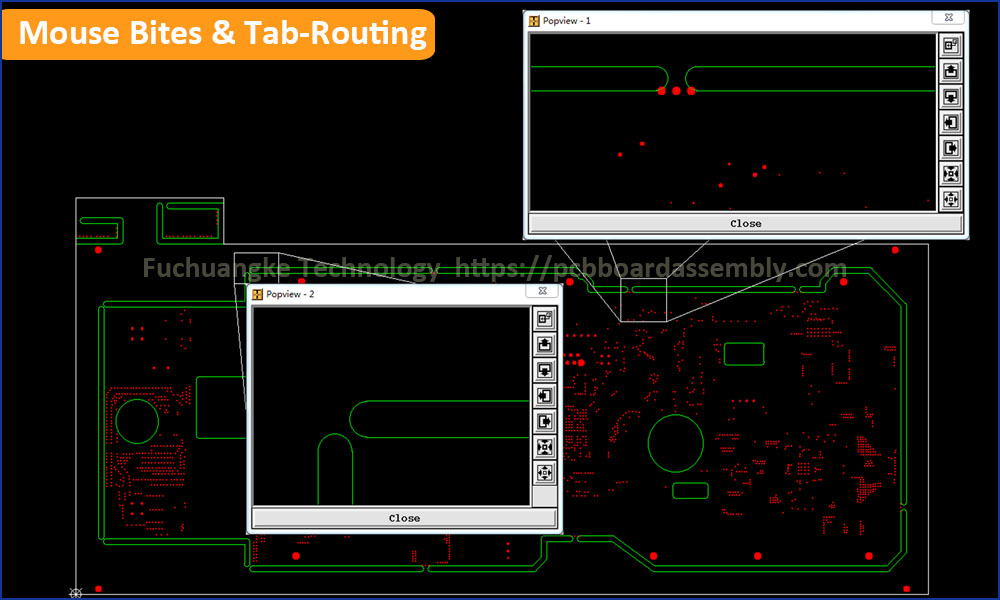

- In PCB Depanelizing, routing is a common PCB panel seperation method like V-grooving (V-cut), but performed by a router. Routing requires that single boards are connected using tabs in a panel (Tab-routing). The bit mills the whole material of the tab. Routing working efficiency is much lower than V-cut, excessive routing will increase PCB cost. But the routing is easier to depanelizing than V-cut, and has smoother board edge than V-cut after PCB assembly.