One-stop Electronic Assembly Services

Electronic Assembly Services. -Fuchuangke Technology

As the global economic integration is developing readily, there will continue to be a need for skilled electronic assembly manufacturers that can build smaller, more durable and more precision electronic products. Since foundation, Fuchuangke Technology has been distinguishing itself as a leading Electronic Manufacturing Company in printed circuit board (PCB) assembly, testing and contract manufacturing for demanding clients in the Consumer Electronics, Medical, Vehicle, Telecommunication and Industrial markets.

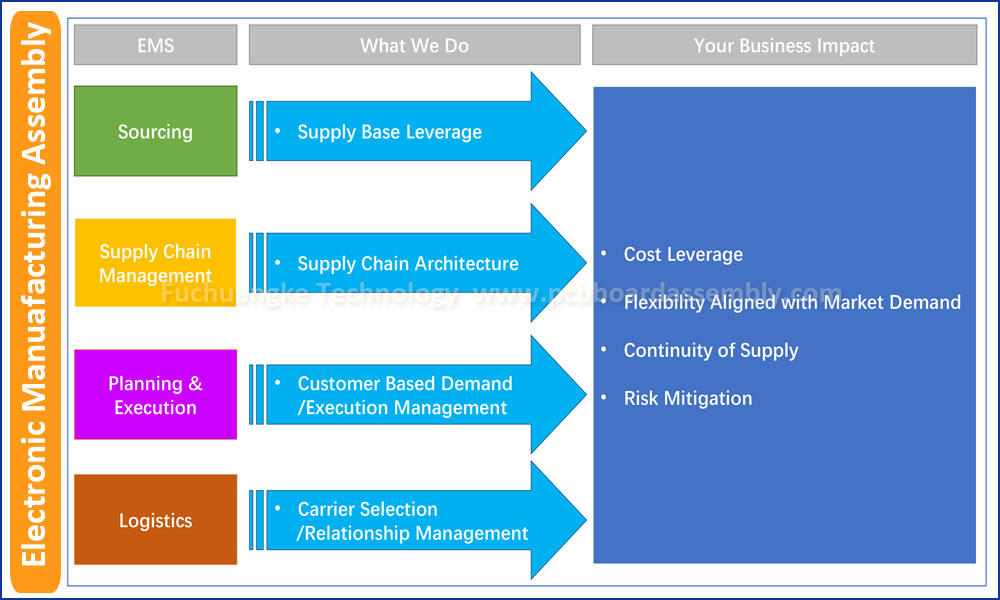

We are fully equipped to provide electronic manufacturing services (EMS) from PCB and PCB assembly prototyping, low-volume and high-volume with a fast turnaround time and a high degree of quality control. Our team of experts in electronic manufacturing is known for its operational excellence and we work collaboratively to design and implement tailored supply chains to each customer’s individual needs to bring flexibility and speed to meet demanding deadlines.

What Are Our Electronic Manufacturing Services?

Fuchuangke Technology has the well-trained personnel and advanced facilities equipment necessary to meet all of your electronic assembly requirements, from electronic prototype to mass production run. We are capable of providing:

- PCB Fabrication: Our printed circuit board fabrication includes FR4 PCB, flexible circuits and rigid-flex PCB, HDI board, IMS PCB, and hybrid laminated circuit boards. All PCB fabrication and electronic manufacturing are made in our own facilities under one-roof.

- Components Sourcing: Components sourcing is a key part of our electronic manufacturing services. We take care of comprehensive components sourcing to improve our PCB assembly production efficiency, and enable you designers and engineers have more time on research and development, engineering and design.

- SMT PCB Assembly: Surface mounting is a technology of manufacturing printed circuit boards that produces smaller products, more quickly, and at a lower cost. As a result, it has emerged as an advanced method of PCB manufacturing for almost all commercial applications. Our automated surface mount manufacturing as part of the larger electronic assembly process. We perform all work to IPC standards in lead free variants. Click to check our PCB Assembly Manufacturing Capabilities.

- Thru-hole PCB Assembly: Thru-hole manufacturing is an older technology of PCB assembly that produces stronger bonds between boards and their components, leading to more durable soldering products overall. As a result, many heavy-duty applications -including vehicle, aerospace and military manufacturing where products are frequently subject to extreme environmental and mechanical stresses – still require thru-hole circuit board assemblies. We are fully qualified to perform thru-hole PCB manufacturing for these and other demanding clients.

- Testing and Inspection: Testing and inspection is a critical step in the electronic assembly process. We have implemented organization-wide control processes and invested in sophisticated equipment to make sure all items that leave our facility meet our customer’s expectations and requirements. We can perform visual inspection, solder paste inspection (SPI), AOI, X-ray, first article inspection (FAI), functional testing (FCT) to your specifications and will work with you to develop appropriate testing routine that provides peace of mind and quality assurance.

- Contract Manufacturing: Contract manufacturing can involve any of the above electronic assembly services. As a China leader in contract manufacturing, we provide and testing, we also offer box building using customized enclosures, components sourcing and drop delivery services. Another service we provide is First Article Inspection, which can be done by us or by you before high-volume assembly. We are the trusted one-stop electronic manufacturing provider which you can contract with all jobs, PCB fabrication, components sourcing, assembly, programming, FAI, functional testing and box building.

Global customers come to us from a wide range of industries and fields. In the past, we have provided short production runs, and now we provide long-term production run and custom manufacturing upon our flexibility to adapt our services to meets the different needs from our customers.

Customer Focus Team Provides Better EMS Service

For keeping step with the fast-moving and dynamic business environment, we are prepared well to fully support your electronic manufacturing challenges relied our knowledgeable and skillful Customer Focus Team (CFT) to adequately support your business. Every role in our CFT are experienced and professional, knows how to understand your business requirements quickly and effectively supports your overall product strategy. In the communication with our CFT, you can easily leverage our range of capabilities in engineering, production, logistics and quality management for being competitive.