What is PCB Assembly Should Cost Analysis?

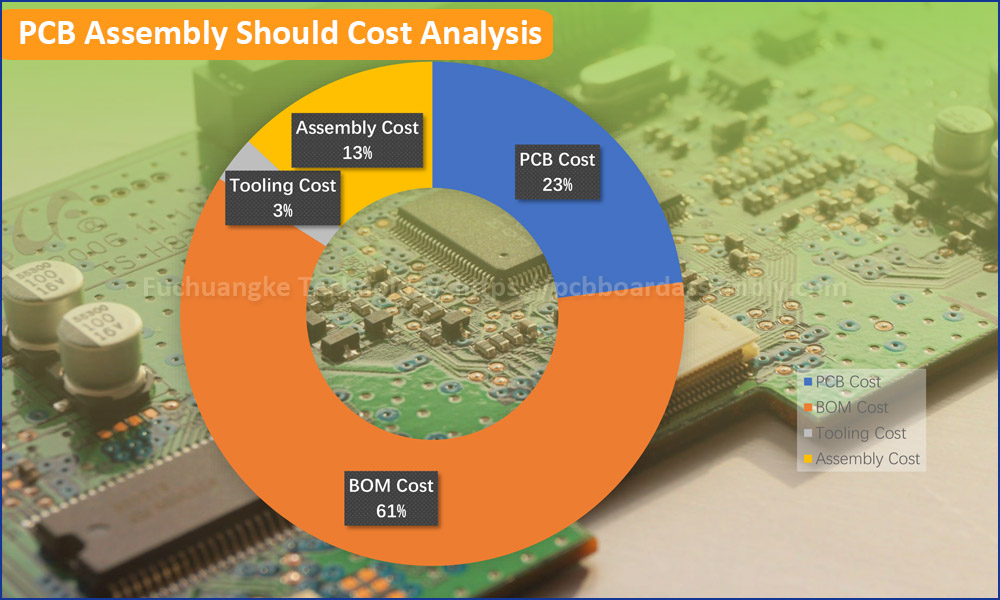

“Should Cost Analysis” is adopted by industry beginning in the 1980’s, and today is the dominant technique used by best in class outsourcing companies. Turnkey PCB Assembly Should Cost Analysis involves determining what a product should cost based on PCB cost, BOM cost, tooling cost and assembly cost in turnkey PCB assembly service.

PCB Assembly Strategic Sourcing

The most common procurement method is strategic sourcing, in which supply chain professionals identify a range of potential turnkey PCB assembly suppliers, usually diversifying between size, capabilities, geography, and many of other potential factors. The selected suppliers are then given the opportunity to quote their PCB assembly project. Supply chain analyzes the quotes to make a sourcing decision. This process is referred to as strategic sourcing. It is the most appropriate approach when the PCB assembly suppliers’ services being procured.

But when can you do if the Printed Circuit Board (PCB) is customized? And different BOM list or SMT tooling, fixture from any available products? The best solution is to submit RFQ to multiple turnkey PCB and assembly vendors, and compare the quotations. This logic of PCB assembly strategic sourcing has proved to work well. By comparing quotations from multiple potential turnkey assembly manufacturers, the supply chain gets insights that can be used to leverage spend. It is largely responsible for driving offshore procurement as companies search for the lowest possible comparative quotation. Such strategic sourcing method is particularly useful to organizations that lack the resources to effectively analyze what the PCB assembly product should cost.

Expected Cost in Internal Assessment

In contrast to PCB assembly strategic sourcing, Should Cost begins with an internal assessment of the PCB assembly expected cost. Generally, engineering from PCB designers, Hardware designers and software designers will be much helpful to assess the necessary PCB cost, BOM cost and tooling cost. Procurement gathers the expected material costs, and supply chain assigns expected assembly cost and profit margins. Supply chain collects the costs and sums them to determine should cost.

In the case of printed circuit board assemblies (PCBA’s), note that Should Cost still utilizes strategic sourcing. This is because PCBA’s cost structure is typically more than 80% materials (PCB and BOM cost) in high-volume PCB assembly projects, and it is not reasonable to fully analyze the fabrication cost of every component, so they must cost materials using strategic sourcing techniques.

Most hardware companies do not conduct should cost for PCB assemblies because they believe the process is too complex and time consumption for their existing resources. Upon closer inspection, this is probably not true. Remember, materials is likely 80% of your PCBA cost. By simply taking control of your material cost you will have achieved 80% of your Should Cost goal. You can begin by requiring your suppliers to submit quotations with fully disclosed material costs, especially each line of the BOM. Even if most turnkey PCB assembly manufacturers don’t like this. Then you can focus your resources on negotiating directly with the component suppliers of the highest cost materials, such as ICs. This will require a contract manufacturing partner who is willing to provide direct manufacturing cost.

How to Choose Potential Turnkey Assembly Supplier?

If only focus on the lowest possible PCBA project cost, it’s simple, and you can choose the turnkey supplier who provides you the lowest quotation. But real strategic sourcing is not only focus on the lowest one, while Should Cost should take other key factors into consideration.

- Certified PCB Assembly Manufacturer

Making sure the potential turnkey service manufacturer has necessary certificates, like ISO9001. You surely don’t want to place PO at a startup company where you project will serve merely as a learning experience.

- Quality Control

A good quality PCB assembly is from a good bare PCB board manufactured with high-level copper clad materials (CCLs). Does your potential turnkey PCB manufacturer source CCL from high-quality suppliers? Besides, a good quality PCB assembly is also from good electronic parts. Does your potential supplier source components from reliable supply chain?

- Engineering Support

Design for Manufacturing (DFM) is very important, which decides whether your PCB assembly is manufacturable. Besides, stencil, SPI, AOI, X-ray, FAI, FCT, SMT carrier, Programming fixture /jig, testing fixture are also very important engineering support in your PCB assembly. Whether your potential turnkey PCB and assembly manufacturer has such engineering support or process?

- PCB and PCBA Testing

Do they provide 100% electrical test (E-test) service before uploading your bare PCB to the solder paste printer? And do they have capable of conducting functional testing (FCT) service?

- Manufacturing Experience

Working with an experienced turnkey assembly supplier will be ideal, which knows precisely how to control the PCBA quality at the very beginning step from PCB manufacturing, SMT machine program optimization, reflow profiling, defects prevention, surface mounting, fixture customization, testing and etc. All you want to do under one roof, the experienced PCB assembly supplier will meet and beyond your expectations.

- Turnaround

Turnaround of turnkey PCB assembly project includes lead time of PCB manufacturing, components sourcing, assembly and testing. And the key factor to the quick turnaround is the components sourcing lead time. Whether the supplier supports quick turnarounds?

In this PCB blog, we won’t list all factors need to be considered to choose the best turnkey assembly supplier, but choosing the lowest possible manufacturer is not advisable. Fuchuangke Technology is the trusted turnkey PCB and assembly manufacturer with its own PCB manufacturing facilities and assembly facilities in Shenzhen. We support quick quote online of bare and PCB assembly.

FR-4 PCB Quote Flexible PCB Quote Rigid-Flex PCB Quote IMS PCB Quote