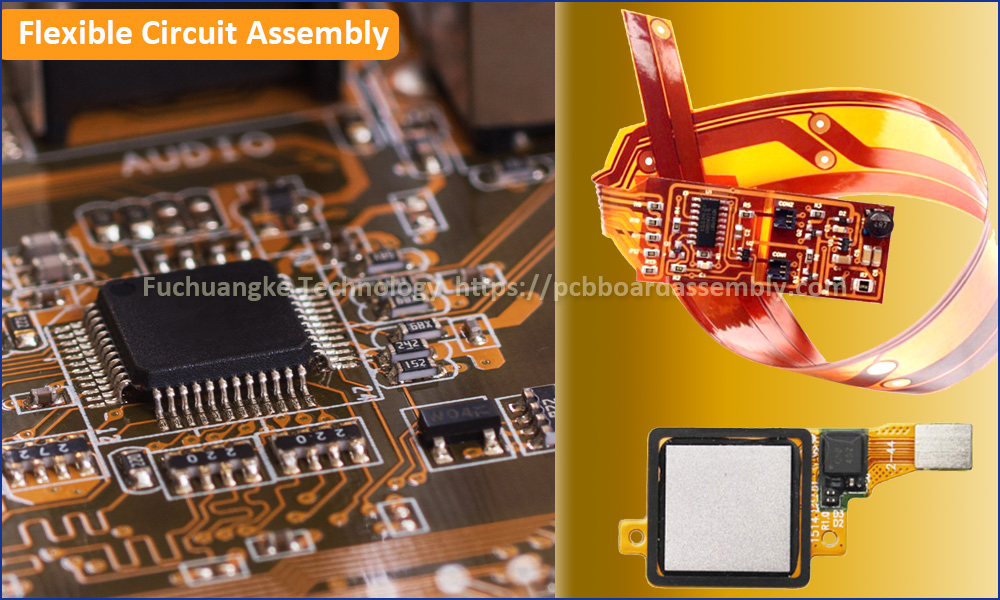

Flexible Circuit Assembly Services

Are you building a product that requires a reliable Flexible Printed Circuit Board (PCB) Assembly Manufacturer? If so, no find more but Fuchuangke Technology, which provides turnkey PCB assembly services for flexible circuits, rigid-flex boards and rigid PCBs. We have our own PCB manufacturing house and PCB assembly house, understand the nuances of assembling on flex circuits, like FPC SMT carrier and special flex circuit assembly depanelization tooling. Turning your flex circuits assembly schedule to us, our highly-skilled and experienced engineering team will plan FPC assembly prototype, low to high-volume assembly, test and shipping.

Turnkey Services Provided for Flexible Circuit Assembly and Rigid-Flex Board Assembly:

- Automated surface mounting technology (SMT)

- Components Sourcing

- Manual Insertion and Soldering

- Connector and Jack Assembly

- Automated Optical Inspection (AOI)

- First Article Inspection (FAI)

- Functional Testing (FCT)

- Customized SMT Carrier

- Special Flex Circuit Assembly (FCA) De-panelization Tooling

Flex Circuits Assembly is a little different from rigid PCB assembly, but don’t worry, the equipment and expertise we have are able to handle assembly of all types and technologies to single-sided, double-sided, multilayer, rigid-flex and rigid. With our own components supply chain, including digi-key, mouser and other famous components vendors, high quality turnkey flex circuit assembly and rigid-flex board assembly will be supplied you on time and on budget.

What Makes Flexible Circuit Assembly Different?

Flexible Circuits have changed the way product development PCB engineers can design and package. Flex circuit applications have opened the doors for PCB Assemblies to move out of square, box enclosures and fit into small, tight, even oddly shaped 3D spaces. But for most PCB assembly manufacturers, flex circuit assembly are some things more painful because the quality of the assembled flex circuits is unstable. For meeting the challenge of flex circuits assembly, Fuchuangke Technology has come up with a variety of techniques to overcome specific flexible circuit assembly hurdles.

1.Custom Flex Circuit Assembly Carrier

Flexible circuits don’t play by the same rules as rigid PCB in the assembly process – They are light, bendy, and can be heat sensitive. To ensure optimal quality and guarantee that the circuits will not be damaged in pick-and-placement machines and reflow oven, a flexible circuit must have strong support. The support is a special SMT carrier with good fixing ability. Generally, any circuit or PCB thinner than 32mil (0.8mm) requires a SMT carrier (/pallet) for the assembly process. This SMT tooling will ensure the board or FPC doesn’t bend or get damaged during flex assembly manufacturing. SMT carrier design is special customized to appropriately support a flex circuit assembly. We work closely with carrier suppliers to design the ideal carrier for each specific flex circuit assembly upon the difference of single-sided or double-sided assembly.

Flexible circuit assembly is completely manufacturable if done everything right, including FPC design itself, panelization and tooling. A good customized SMT carrier is the most important thing for flexible circuit assembly. When design the SMT carrier, the engineers should consider material, thickness, and access hole’s location, quantity and size, and FPC or rigid-flex cut-out that the assembly can sit into perfectly.

SMT carrier also helps to ensure that the flex circuit assembly is conveyed to the machines at a consistent height. In the case of solder paste printing applications, its crucial that the flex circuit assembly is at a specific height for even distribution of paste. If the assembly doesn’t enter the machine properly, the paste won’t print correctly and gasketing issues can arise, which will cause assembly defects later.

In the case of SMT pick-and-place machines, the SMT carrier for the flexible circuit ensures the assembly is also conveyed to those machines at the ideal height. High-speed SMD placement machines don’t leave much room for error, so the flex circuit assembly must be adequately prepared and supported for those fast placements.

2. Soldering Temperature Control for Flex Circuit Assembly

Beyond the carrier tooling support, manufacturing engineers and technicians need to pay attention to the soldering heat applied to flex circuits during reflowing and manual soldering. Since flex circuits are typically very thin, there’s nowhere for the heat to go besides into the barrel, so thru-hole parts must be soldered at lower temperatures. Manual soldering a flex circuit can be challenging, and requires an experienced technician to utilize the perfect techniques.

For example, when manual soldering a normal rigid PCB, you can touch the PCB board for 3-5 seconds with a temperature range of 250-340?, but with certain flex circuits, you can only touch that board for 1-2 seconds at most and the heat is much lower at about 245?.

3. Different Flex Circuits Assembly Testing

When it comes to flex circuits testing, the same support and tooling rules apply. All flexible circuits require appropriate backing to support the assembly during the testing process. In the case of flying probe testing, a special customized fixture should be developed to provide that support to the PCBA when it’s being probe tested.

When it comes to flex circuits testing, the same support and tooling rules apply. All flexible circuits require appropriate backing to support the assembly during the testing process. In the case of flying probe testing, a special customized fixture should be developed to provide that support to the PCBA when it’s being probe tested.

When it comes to flex circuits testing, the same support and tooling rules apply. All flexible circuits require appropriate backing to support the assembly during the testing process. In the case of flying probe testing, a special customized fixture should be developed to provide that support to the PCBA when it’s being probe tested.

For ICT, a rigid backing is usually designed into the clamshell fixture. While this can add mechanical challenges for ICT development, it’s needed to ensure safe testing of the flex circuit. Additionally, low force probes should be used to avoid any unnecessary damage to the flex’s fragile surface.

During the FCA testing process, flex circuit assemblies don’t always have tooling holes to use as guides, so it’s important to use a fixture or cut-out that the flex assembly can fit into perfectly. Traditionally it can also be difficult to access test points on flex assemblies. Without exposed thru-hole vias, test technicians have limited access to probe the assembly. Additionally, designing in appropriate test access points is sometimes overlooked with flex products. Electrical engineers should design in appropriate test points during the product development stage.

4. Flex Circuit Assembly De-Panelization

Flex circuit assembly de-panelization can also be tricky. In rigid PCB assembly, PCBA de-panelization can be done by hand and CNC machines upon order volume. Hand de-panelization can lead to poor quality control and repeatability issues in manufacturing. CNC machine de-panelization can be applied to rigid PCB assemblies, but not applicable for flex circuit and rigid-flex PCB assembly because it may tear and break the FCAs. There are 2 different de-panelization methods are available for flex circuit assembly. One is laser cutting and another is punching by machine with special punching die. Laser de-panelizing is gaining popularity, and while much more precise than hand cutting, but it’s a far more expensive solution with lower de-panelization efficiency than punching.

Both laser and punching methods in flex circuit assembly are the same as that of flex circuit manufacturing during coverlay cutting and FPC profiling. But the punching die in FCA de-panelization is more than different that of punching profiling. When understand and apply this de-panelization punching method, Fuchuangke Technology became a leading Flex circuit assembly manufacturer during whole Shenzhen. More questions about the custom SMT carrier and De-panelization punching die, feel free to contact us.

Quick Quote

Click the Quick Quote buttons below, you can turn to the different PCB quote pages. Just fill in the PCB specifications, upload Gerber files, BOM, Assembly Drawing and Pick-and-Place file, you will get quick quote of PCB board and PCB Assembly.

FR-4 PCB Quote Flexible PCB Quote Rigid-Flex PCB Quote IMS PCB QuoteFuchuangke Technology is a leading Turnkey Flex Circuit Assembly Manufacturer in Shenzhen, provides flexible PCB, flexible circuit manufacturing and assembly.