SMT First Article Inspection on PCB Board Assembly

Fuchuangke Technology is full understanding the importance of lead time and PCB assembly accuracy for customers, and that’s why we double confirm the PCB file before printed circuit board (PCB) manufacturing and assembly. If found any concerns or engineering questions on your PCB board during fabrication, our team will communicate quickly. When bare PCB board production get 100% qualified outcome, it goes to the next process in the turnkey PCB service – SMT assembly and DIP assembly.

As a leading quick-turn PCB and assembly manufacturer, our SMT house is equipped with SMT FAI system FAI-600, which offers powerful automated PCB assembly manufacturing verification test. With its help, our SMT engineers can quickly and accurately verify first article samples. The testing method consists of measuring the properties and geometry of an initial SMT PCBA sample against given specifications.

Before the electronics manufacturing begins, customers always require an in-depth verification and comparability of PCB design and manufacturing outcomes, often called First Article Inspection (FAI). Frequently used within the aerospace, medical and automotive electronics, FAI studies have got an ordinary course of to make sure high quality and consistency of the ultimate product is in order. Although conducting FAI could be advanced, technological developments and person pleasant software programs have allowed customers to implement and execute this course of shortly and precision.

What is First Article Inspection?

As an official authentication technique for PCB board assembly production, FAI intention is to overview and authorize dimensional studies. FAI stories make the most of dimensional properties of a manufacturing like design specifications, to make sure of consistency or uncover any deviations. This inspection ensures reliability and repeatability of the manufacturing course, in addition to making certain the PCB assembly manufacturer’s capabilities to provide elements in accordance with specifications.

What is the FAI Purpose?

- The FAI report supplies a tenet for goal affirmation that every engineering design and specification is appropriately understood, accounted for, verified and documented.

- Ensure the SMT assembly manufacturing course of action is dependable, repeatable and constant.

- Develops a transparent understanding and communication outlet between customer and assembly provider.

- Verify the accuracy of drawings, making certain that each adjustment made to any part of the designs are accounted for.

- Validate all tooling used for PCB assembly production, guaranteeing the instruments’ capabilities to supply all required elements at defined and accepted speed.

- Ensuring PCB and assembly manufacturing course is successful and might meets the entirely of all manufacturing needs.

When is SMT FAI Report Required?

- A change in PCB design which may probably have an effect on match, kind or operation.

- A change in manufacturing supply, course of action, inspection technique, location of producer, tooling or supplies.

- A change to a special media program that will likely have an effect on match, kind or performance.

- PCB and assembly production have not been executed for 2 years or more (or as specified by customer)

PCBA First Article Inspection Process

- Uploading Files & Testing Program: choosing and uploading the PCB image, PCB Gerber files, and BOM file, the FAI system will analyze them and automatically generate a testing program quickly.

- Auto Check: For components soldered onto the PCB board without markings, a built-in LCR meter will perform test measurements for Inductance (L), capacitance (C) and resistance (R). Upon BOM information, the FAI system automatically changes the test frequency.

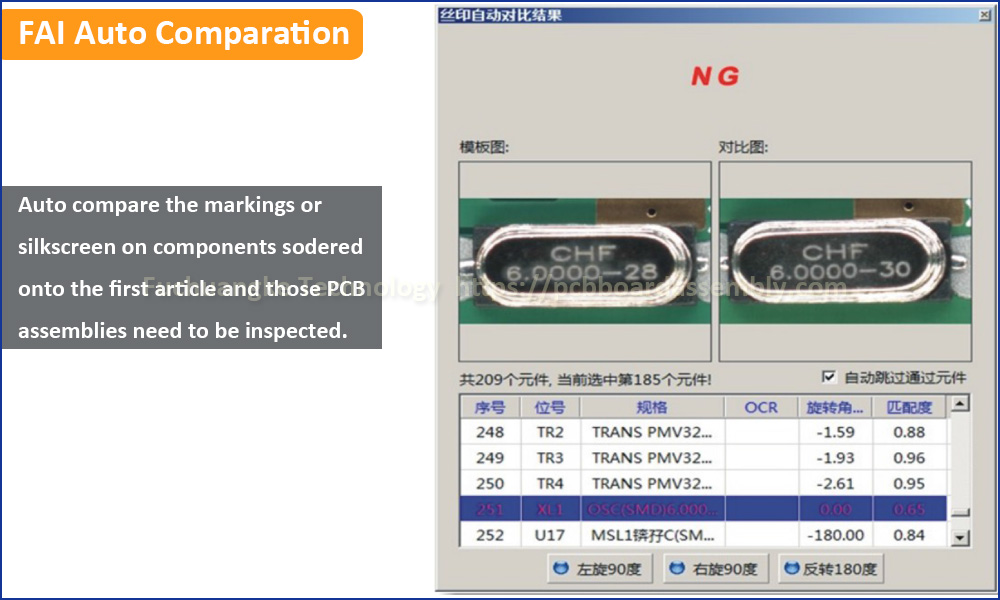

- Auto Optical Inspection and “Golden Board“: For components with silkscreen, SMT FAI machine checks all components in under a minute. A “Golden Board” can serve as a teste reference for afterwards PCB board assemblies.

- Detailed Search: FAI report data can be viewed and sorted in a number of different ways. For example, components can be sorted according to whether they have passed or failed a measurement test, or by their part numbers.

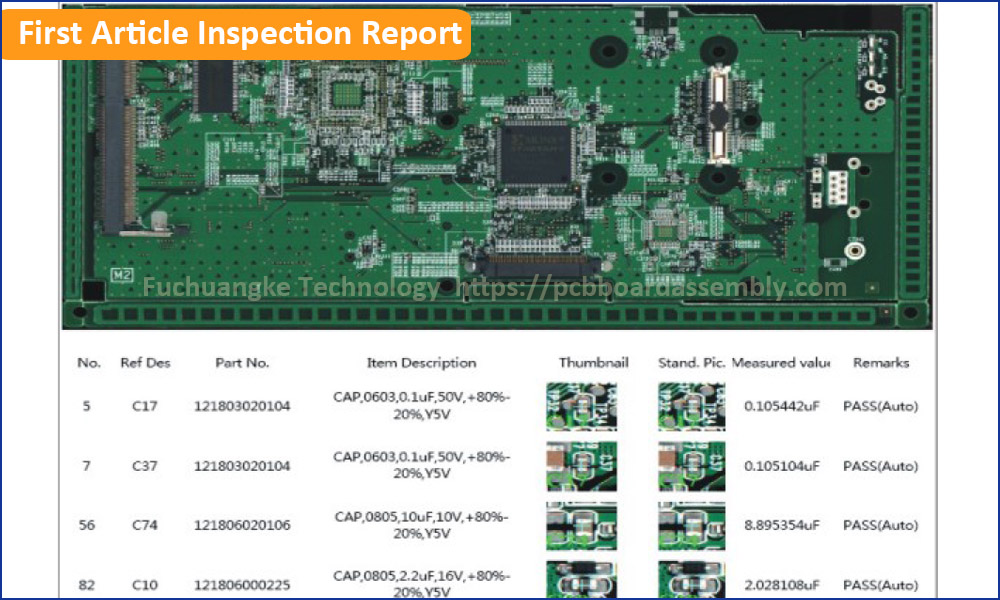

- First Article Inspection (FAI) Report: Each FAI report includes the company’s name, test time, operator’s name, project model number, total number of components, how many components passed and failed measurement. The measured values of all LCR components and their nominal values are also shown. Reports can be viewed, printed, saved or emailed to customers.

Auto PCBA First Article Inspection Advantages

| Criteria | Auto FAI | Note |

| Labor | One Operator | 50% labor cost savings |

| Testing Speed | Very fast | 80% faster than traditional method |

| Accuracy | Excellent | 99.99% accurate and reliable |

| Vision | Clear | Latest optical technologies |

| Verification | Auto | Prevent labor inspection |

| Report | Detailed | Can be viewed, saved, printed & emailed |

| Auditing | Yes | The operator needs to sign in to make auditing |

For getting the perfect PCB assembly outcome, we perform SMT First Article Inspection (FAI) and confirm the “Golder PCBA” as preference for further assembly manufacturing. Besides, we also conduct solder paste inspection, auto optical inspection, X-ray inspection, In-Circuit Inspection and functional testing (FCT) on every PCB assembly project. If in demand of high-precision and high-volume PCB assembly, you’d better to find a turnkey assembly manufacturer who is capable of providing you SMT FAI report, like Fuchuangke Technology.

Related PCB Blog: How Much Do You Know PCBA First Article Inspection

Quick Quote

Click the Quick Quote buttons below, you can turn to the different PCB quote pages. Just fill in the PCB specifications, upload Gerber files, BOM, Assembly Drawing and Pick-and-Place file, you will get quick quote of PCB board and PCB Assembly.

FR-4 PCB Quote Flexible PCB Quote Rigid-Flex PCB Quote IMS PCB Quote