Why Develop A PCB Prototype Board?

Highly reliable electronic designs require accurate and quality manufacturing at their root. PCB Prototyping is a crucial stage of electronics project development, in which allows the hardware engineers to design and modify their printed circuit board design, and the software engineers to test the outcome on Prototype PCB Assembly; often taking multiple runs to perfect their designs.

The main intention of PCB prototyping or PCB assembly prototyping is not only to test the concept and functionality of the design, but also to perfect and grow it step by step, limiting final PCB and assembly fabrication failure as much as possible. If the high-volume PCB assembly runs on an unexpectedly defect golden sample, the rework time and cost are hard to count. This should save unnecessary additional costs and extended project times. Perfecting your PCB design on prototyping is obviously important before production. Once everything is proven by testing, just keep the final PCB prototype and PCB assembly prototype as the golden sample. All afterwards PCB manufacturing and assembly should follow it, including PCB materials, stack-up, process, BOM components, reflow profiling and program may be uploading to the main chips.

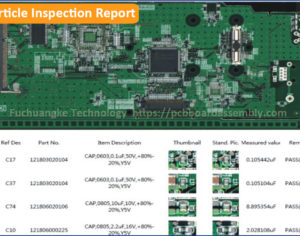

Speed and flexibility are often the main focus of this PCB prototype board development stage facilitating rapid testing of ideas and amendments where appropriate. Companies desire fast turnaround prototype PCB and prototype PCB assembly as the quicker the design can be verified, the quicker the electronic products get to market optimizing sales revenue potential and profitability. No find more, but Fuchuangke Technology, which is reliable turnkey PCB and assembly manufacturer. Just submit your job, including Gerber file, BOM, pick-and-place (coordinates) file, and testing procedure documentations, to us, our professional team will arrange quick PCB and assembly prototyping for you. In the assembly stage, prototypes can go through SPI (solder paste inspection), AOI, X-ray, FAI (first article inspection) and FCT (functional testing) under one roof. For your attention, we can provide PCB assembly first article report with BOM components values measured, which can be an importance reference for your further perfection on your PCB design.

PCB Blog: SMT First Article Inspection on PCB Board Assembly

Types of PCB Prototypes

- Limited Function: Test out each intended final function of a PCB board within single function boards.

- Functional Concept: proves the concept of the circuit built up without full capabilities.

- Working prototype: Fully integrated functions which will be refined through further runs

- Fully Functioning Prototype: Combines all aspects of functionality intended for the finalized PCB design as well as adapted characteristics that have been developed through the runs. This prototype will reflect the final production golden sample.

Main Benefits of PCB Prototypes

- Helps to reduce the time from idea to market

- Allows you to test design in small quantities before primary large production

- Ensures manufacturability

- Ensures functionality

- Cost effective for multilayer PCB or high-density (HDI) PCB

- Reduces costly reworks

- Fine-tuned, validated designs

- Eliminate failures early

How Fuchuangke Technology Can Help?

It’s a common misconception that good value and low volume PCB fabrication and PCB assembly do not go together. Here at Fuchuangke Technology, a China-based PCB assembly manufacturer and provider, we specialize in providing a low cost quick turnkey PCB assembly prototype service. Click the Quick Quote buttons below, you can turn to the different PCB quote pages. Just fill in the PCB specifications, upload Gerber files, BOM, Assembly Drawing and Pick-and-Place file, you will get quick quote of PCB board and PCB Assembly.