What’s The Difference Between PCB and PCBA?

If you have experience in electric and electronic manufacturing industry, you may understand the term PCB and PCBA. PCB is the abbreviation of Printed Circuit Board, and PCBA is that of Printed Circuit Board Assembly. What are they?

What’s Printed Circuit Board (PCB)?

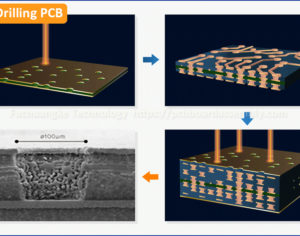

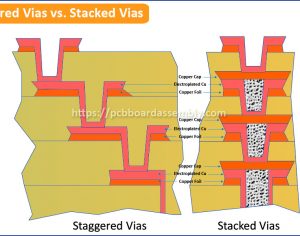

A PCB is an important electronic component, which is the mechanic foundation in which electronic components, such as resistors, capacitors, inductors, ICs, connectors and etc., can be mounted to complete an intended circuit, then realize the function of the PCB design. No matter it is Rigid or flexible, the PCB itself are made of base material (typically resin epoxy and polyimide), copper, PP or adhesive, with or without surface finish, solder mask and silkscreen. The copper will be processed as pattern/trace, and the dielectric base material will be the mechanic support. The “print” process is transferring the pattern in the cam file to the copper on the base material. Upon different layer count, the PCB can be divided into single-sided, double-sided, 4, 6, 8, 10 and higher multilayers with non-plated holes (NPTH) or/and plated holes (PTH), like thru-holes, blind vias, buried vias, staggered vias and stacked vias. The hole size decides the drilling method. Generally, holes with diameter equal or bigger than 0.2mm will be dilled by NC machine, otherwise by laser drilling machine. Laser machine can drill 3mil, 4mil, 5mil and 6mil holes. Through holes connection, the traces between copper layers can be connected and to be multilayer circuit boards. Printed Circuit Boards without electronic components soldered is called PCB.

What’s Printed Circuit Board Assembly (PCBA)?

Printed Circuit Boards with electronic components soldered is called PCBA, which is the abbreviation of Printed Circuit Board Assembly. All PCB boards will be fabricated to be PCB assemblies to realize its function and value in product after box assembly. Of course, the entire process of PCB assembly is complex but not hard to understand. The 2 main process to PCBA is SMT assembly and DIP soldering. Surface Mounted Devices (SMDs) will be placed onto the bare PCB pads with pre-printed solder paste. Put the unsoldered PCB into the reflow oven, the solder paste will go through melting, cooling, and the SMDs will be soldered to the PCB. Besides, there are DIP components and plastic connectors. With similar method, they will be soldered to the PCB after SMT assembly. Through assembly, visual inspection, SPI, AOI, X-ray and FCT, a PCB with components becomes a functioning printed circuit assembly (PCA), or the PCBA.

Difference between PCB and PCBA?

A PCB is a board used to electrically connect and mechanically support components using pads, conductive tracks and several other features etched from sheets of copper lamination onto non-conductive base materials. PCBA is the board obtained after all printing solder paste on the PCB and then mounting various components like active and passive components. In a word, a PCB (printed circuit board) has no electronic components onto its surface, while a PCBA has electronic components onto its surface.

Printed Circuit Board Assembly Manufacturer

We are an experienced PCB Assembly Manufacturer for all your PCB and PCBA fabrication demands. From printed circuit board fabrication, SMT, DIP, mixed assembly, X-ray, Functional Testing to electronic device subassembly and complete product build, we deliver our professional acknowledges, technologies and experience to provide quality electronic PCB and PCBA products for OEMs on-time and within budgets.

Quick Quote

Click the Quick Quote buttons below, you can turn to the different PCB quote pages. Just fill in the PCB specifications, upload Gerber files, BOM, Assembly Drawing and Pick-and-Place file, you will get quick quote of PCB board and PCB Assembly.

FR-4 PCB Quote Flexible PCB Quote Rigid-Flex PCB Quote IMS PCB Quote