5 Tips for Working with China PCB Assembly House

When everything prepared well with your bare printed circuit board, including PCB design and PCB prototyping. What’s next when you want to bring your product to market? Well, aside from choosing your trusted quick PCB manufacturer, you’ll also need to find a supplier to professionally assemble the BOM required components to your PCB board. But how do you think find a turnkey PCB assembly house in China? Which helps PCB fabrication, components sourcing, PCB assembly and functional testing for you. While choosing the right PCB assembly house may seem dauting, we’ll share a few practical tips to ensure your next turnkey PCB project goes smoothly.

Contact Early and Often

Are you a buyer? Or no matter what role you play in the PCB manufacturing and assembly project. Your engineer, designer or R&D team spent much time, effort and passion into every detail in the whole design phase. Why would you always ask someone else in your potential PCB assembly suppliers to assume what you want? Just open a line of contact with a sales manager, and send all files required, like Gerber files, BOM, pick-and-place, assembly drawing, testing procedures and special fab notes, to make sure your newly-designed project will be built exactly how you’d expect it. Besides, the PCB assembly house probably has resources you haven’t thought about. Since these professional engineers are experienced working with a lot of PCB assembly projects, they can provide invaluable review feedback on your project such as:

- Whether the design has PCB DFM (design for manufacturing) problem, or not? And advice on effective your PCB design.

- Components availability feedback and alternative components suggestion to solve availability issues.

- Assembly panel suggestion to improve SMT work efficiency and reduce cost for your project.

PCB Assembly in China Will Reduce Cost but Not Sacrifice Quality

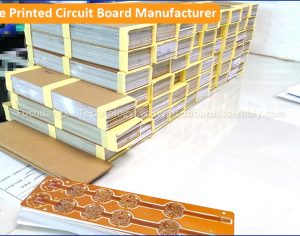

With the development of electronic manufacturing industry, China PCB assembly houses import and equip advanced SMT related machines. The PCB assembly workmanship and after-sales service gradually got much improvements. Plus, China is the biggest PCB manufacturing country in the world. The PCB cost is much lower than that of European and American developed countries. Considering the plant renting cost and labor cost, it is easy to be keep leadership with competitive prices. To be mentioned, low cost PCB assembly is not to sacrifice the quality of your products.

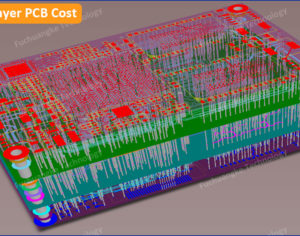

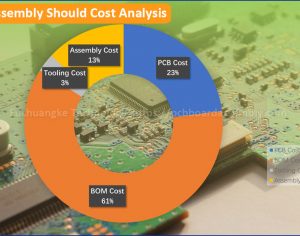

BOM components cost takes up more than about 61%, PCB cost takes up about 23%, assembly cost takes up about 13%, and tooling cost takes up about 3% in the turnkey PCB assembly project. From this data, how to reduce costs of your turnkey PCB assembly projects? The biggest part is components cost. Components always can be divided into active and passive parts. At Fuchuangke PCB assembly house, we have our own components supply chain with 3 components sourcing professionals. That’s why we can offer low cost turnkey PCB and assembly service globally. We support full turnkey service and partial turnkey service, that’s to say, you can ask us to source all components, and you can provide partial main components, like IC at well. Of course, we won’t use alternative components without your approval. If meet some components unavailable, we can suggest alternatives to you, but it is decided by you whether you are willing to use them.

Get All Done in One Source

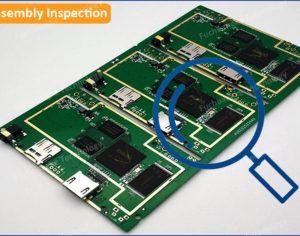

Have you met PCB assembly defects but hard to decide who should bear it in your sourcing experiences? PCB assembly defects maybe caused by many aspects in manufacturing phase, like PCB defect, components defect and assembly defect. If all are done well, there is no defects in your PCB assembli es. If sub-contract one project to 3 different suppliers, the quality risk will increase, and may meet the problem mentioned above. But when get all be done in one source from a professional turnkey PCB and assembly manufacturer, if defects found, you can ask this one supplier to bear all. What’s more, only with one supplier, you can save energy and time at most.

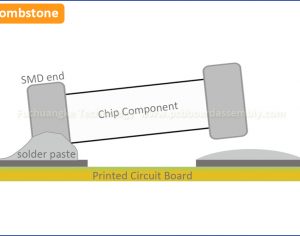

Advanced Assembly Machines and Process

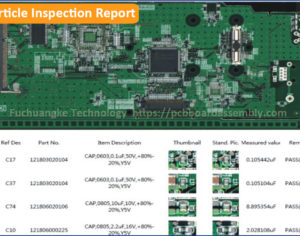

With advanced 8 SMT lines, humidity and temperature strictly controlled warehouse, PCB and components baking oven, first article inspection (FAI) machine, solder paste inspection (SPI), AOI, X-ray, and Functional Testing (FCT). We conduct FAI process for each PCB board assembly project. Only FAI is confirmed ok by us or by your side, the remaining prototypes, or low to high volume production will start. In Fuchuangke PCB assembly facility, we can assemble each component to PCB with high precision, your PCB board assembly can be almost no assembly defects. So, what you need to do is to find and contact a professional supplier with its own components sourcing and management and PCB manufacturing facility to lowest the defects risk.

Understandable and Complete Bill of Materials (BOM)

Bill of materials (BOM) is a list of all electronic components will be assembled in the PCB boards. It shows what parts are needed, where these parts should be placed and assembled. A clear, concise and complete BOM is very important for understanding. Your PCB assembly house will be using this crucial BOM to purchase all the components necessary build your PCBA project, and will match the reference designators to the silkscreen on bare PCB board.

Make sure your BOM is a spreadsheet listing each “line item”, the reference designators related to that line, and a brief description of the component specifications or value. Each component with or without supplier link is acceptable in Fuchuangke Technology. We accept BOM in format of .xls, .xlsx or .csv but not .pdf or .doc. Here is a Sample BOM for your reference, click to download.

The 5 tips in this PCB blog is not an exhaustive list, but they are just a few of the tips we’ve learned over the years from our experience in turnkey printed circuit board assembly as a PCB assembly house Shenzhen China. Both your side and our side are exciting and to finally see your PCBA project exit the PCB design and head into mass production. As a leading turnkey PCB and assembly house, Fuchuangke Technology is capable of providing you flexible circuits (FPC), rigid-flex and rigid PCB fabrication, components sourcing, SMT &DIP assembly and functional testing (FCT) service with low cost and quick delivery time.