3 Ways to PCB Assembly Project Success

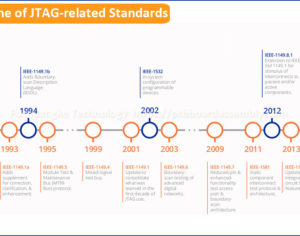

If you are a new comer when it comes to PCB Manufacturing and Assembly, then you may ot know that printed circuit board (PCB) manufacturing and printed circuit board assembly (PCBA, or PCB with components) are different industry field typically performed by different IPC standards and other standards. Of course, PCB manufacturing refers to the fabrication of the bare circuit board, whereas, PCB assembly refers to the placement of SMD and DIP components onto the bare board.

As a turnkey PCB and assembly manufacturer, we’ve written extensively on topics related to PCB Surface finish, Via Finish, Flex Circuit Outline Processing, VCP Plating, Conductive Carbon Ink Printing, Factors That Increase PCB Cost and etc. to have you understood the PCB key technologies we have. But what about PCB assembly process? What steps should be taken to ensure a high-quality, cost-effective outcome? We are a leading PCB assembly manufacturer in SMT industry in Shenzhen, China, and based on our experiences and communications with our customers, here are top 10 tips to make your PCB assembly success.

K1. Keep Contact to Your Turnkey PCB Assembly Supplier, Not Last.

You’ve probably consulted some resources including PCB manufacturer and PCB assembler while you planned your PCB design. Just as we would encourage you to consult one resource, a professional turnkey PCB and assembly producer, like Fuchuangke Technology, on both PCB design and PCB board assembly, then you can save time and energy since no need to communicate with 2 persons at the same time. You can get all information about design modification, PCB assembly panel and others throughout the PCB and assembly manufacturing process. For example, there is a BGA with more than 1 hundred pads, you would like to design it as a 10-layer PCB with thru holes, but the size is limited and you find there are still some traces cannot be routed properly even if you use buried and blind vias technology. The turnkey PCB and assembly supplier may suggest you why not to design it as a 6-layer (1+4+1) HDI board with laser drilling technology. The PCB costs are almost the same, and you learn the new HDI technology you’ve never use before.

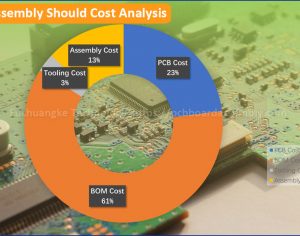

2. Considering the Total Cost of Your Turnkey PCB Assembly Project

A PCB assembly project cost consists of PCB cost, BOM cost, assembly cost and tooling cost. While low-cost assembly may be tempting, but it’s suggested to consider total cost of your turnkey PCB assembly. In Fuchuangke Technology, the total cost will be competitive and the PCB assembly quality is guaranteed.

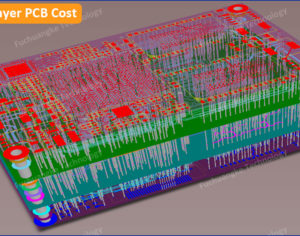

- PCB Cost: You may know the most printed circuit boards in the world are manufactured in China since the PCB cost is competitive than other areas. The PCB cost from us will be cheaper than your PCB assembly supplier without its own PCB fabrication house.

- BOM Cost: We have our own components supply chain in Shenzhen and Hong Kong, they can support us the most components you require to assembled on your PCB board with lower prices. For the hard-to-find components, we use the famous component distributors, like Digi-key, mouser and etc. But don’t worry, all components are 100% original. We won’t replace any one part without your approval. Low BOM cost keeps us leading some other turnkey PCB and assembly suppliers.

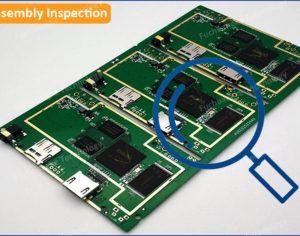

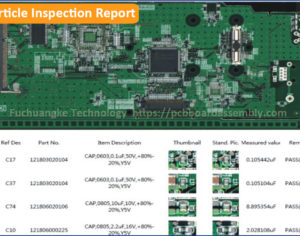

- Assembly Cost: Equipped with 8 SMT lines, and each line configuration is different from each other, which can meet different requirements of component packages and quantities per board to save cost. Low assembly cost in China is not a secret. In our PCB Assembly House, you can enjoy free DFM, first article inspection, SPI, AOI, X-ray and FCT services to ensure PCB assembly success.

- Tooling Cost: What’s tooling? PCB assembly tooling includes stencil, SMT carrier, software uploading jig, functional testing fixture and depanelizing fixture, but not all are required in your PCB project. Our years stable work with our tooling suppliers ensure we can get low cost tooling. Is tooling cost an NRE (Non-Recurring Engineering) cost in Fuchuangke Technology? Yes, it should be and no longer charge in repeat orders.

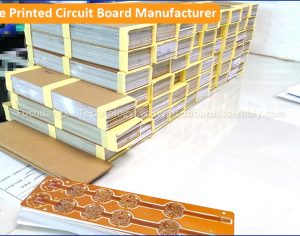

3. Just Visit Your Turnkey PCB Assembly Supplier

Nowadays, many customers worry to work with PCB trading company, and want to work with direct manufacturer. In our position, if the cost and quality is ok from a trading company, you no need to worry when it is prototype PCB assembly project. But if there is middle to high-volume PCB assembly in future. We suggest you to find a real turnkey PCB assembly supplier at the very beginning in prototype stage, then you can get consistent PCB assembly quality from one sole source. Want finding a professional turnkey PCB assembly supplier? The most recommended approach is to visit the manufacturing facilities to check workshop, equipment, PCB and PCBA samples, manufacturing capabilities and service. And check whether the turnkey PCB provider can meet your expectations in your future PCBA projects. Welcome your visit us, we are confidence to be a leading turnkey PCB and assembly manufacturer in Shenzhen, China.

Quick Quote

Click the Quick Quote buttons below, you can turn to the different PCB quote pages. Just fill in the PCB specifications, upload Gerber files, BOM, Assembly Drawing and Pick-and-Place file, you will get quick quote of PCB board and PCB Assembly.

FR-4 PCB Quote Flexible PCB Quote Rigid-Flex PCB Quote IMS PCB Quote